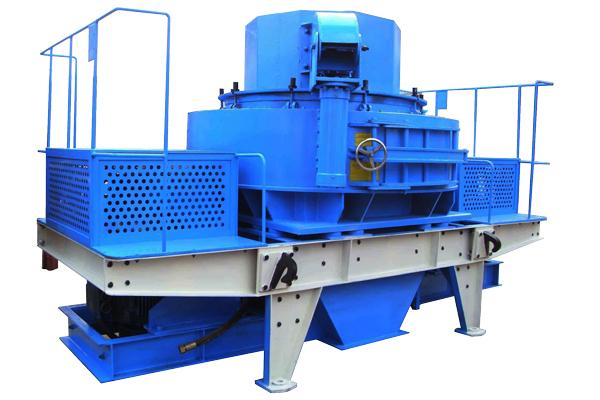

Sand making machine is a special and efficient equipment for making various kinds of sand from hard stone.

VSI sand making machine(VSI crusher) is the latest successful crushing machine with the international advanced technology. Many years technology accumulation and modern processing equipment ensure the leading position of the VSI crusher in this industry. Excellent cost performance and reliability make VSI crusher outstanding in the similar products. VSI crusher is the perfect combination of the latest research result of Germany and Chinese present working conditions. It is currently the exclusive production sand making machine with the worlds advanced level. VSI crusher is suitable for crushing and shaping soft or middle-hard or extremely hard materials, widely applied to pebble, rocks (limestone, granite, basalt, dolerite, andesite), iron ore tailing, artificial sand making of stone chips. It is also applied to water conservancy and hydropower of engineering field, high-grade highways, expressway and railway, passenger railway, bridge, airport pavement, municipal engineering, sand manufacturing and aggregated rock shaping.

Features and technology advantages of sand making machine

1.Simple and reasonable structure, low cost

2.High crushing ratio, energy saving

3.Fine crush and grind

4.Moisture content of raw material up to about 8%

5.Suitable for crushing hard material

6.Excellent shape of final product

7.Small abrasion, easy maintenance

8.Noise when working is below 75dB

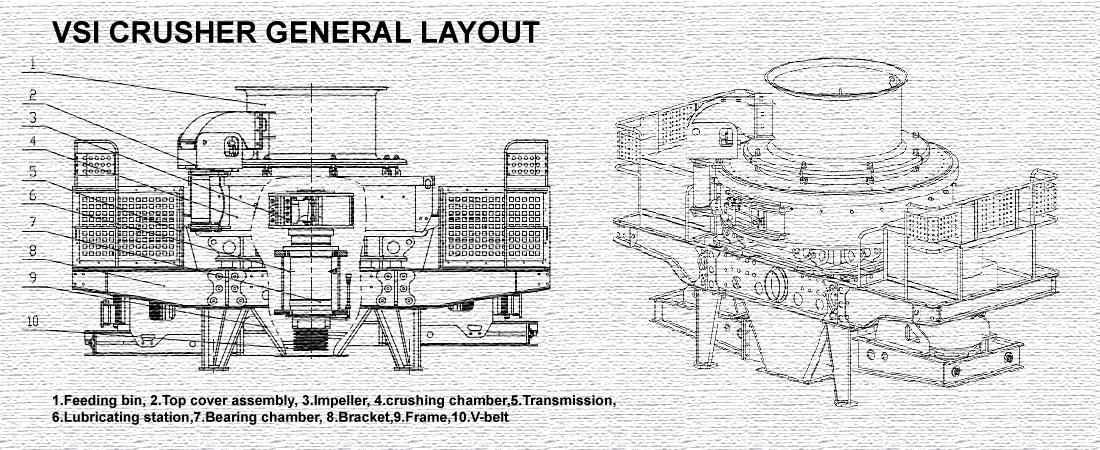

Working principle of sand making machine

The materials fall into impeller with high-speed rotation vertically. On the force of high-speed centrifugal, the materials strike to the other part of material in a high speed. After mutual impacting, the materials will strike and rub between the impeller and the casing and then be discharged straight from the lower portion to form a closed multiple cycles. Final product is controlled by screening equipment to meet the requirement.

Specification of sand making machine

| Model | VSI-7611 | VSI-8518 | VSI-9526 | VSI-1140 | VSI-1145 | |

|

Capacity (t/h) |

Center and Ring Feeding | 120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

|

Center Feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

|

Max.Feeding Size (mm) |

Soft Material | <30 | <35 | <40 | <40 | <40 |

|

Hard Material | <25 | <30 | <35 | <35 | <35 | |

| Rotation Speed (r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| Power for Double Motor (Kw) | 110-x150 | 180-220 | 264-320 | 400-440 | 400-440 | |

| Overall Dimension (mm) | 3700x2150x2100 | 414x0x2280x2425 | 4560x244x7x2778 | 5000x2700x3300 | 5100x2790x3320 | |

| Power Source | 380V, 50Hz | |||||

|

Lubrication Hydraulic Pressure Station |

Power for Double Oil Pump (KW) | 2x0.31 | ||||

| Safety |

The double oil pumps ensure the supply of the oil; Stop working without oil or hydraulic pressure;Temperature falls when the water cools;Start the motor by heating it in winter. | |||||

|

Overall Dimension (mm) | 820x520x1270 | |||||

|

Power for Oil Box Heater (kw) | 2 | |||||

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087