What is a high gradient magnetic separator for sale?

Vertical high gradient magnetic separator is widely used for weak magnetic metal ore such as hematite, limonite, siderite, chromites, wolfram etc as well as iron separation for purification of non-metallic mineral, such as quartz, feldspar, nightline,fluotite, kaolin etc.

Features and technology advantages of high gradient magnetic separator

1. its separation ring is designed to be vertical, concentrate ore is discharged by reverse flow and also with separation pulse device.

2. Powerful magnetic force, reliable and convenience performance.

3.Simple installation and easy to maintain.

Working principle of high gradient magnetic separator

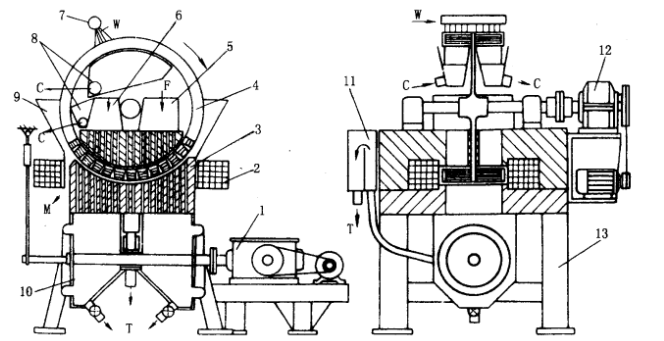

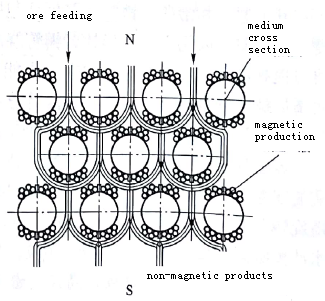

Magnetic yoke fixed on the machine frame, which generate the strong magnetic field together with exciting coil. Rotary ring is in the clockwise drived by the rotary device, and goes through the magnetic field slowly. There are many separation boxes on the outer circle of the rotary ring, there is the multi-layer magnetic medium which is made of magnetic material inside the separation box. When the rotary ring goes though the magnetic field, it would be magnetized, and formed the high gradient magnetic field. In the mineral processing, the mine slurry goes into the rotary ring along with the gap of the magnetic pole, and the magnetic particle would be attracted in the magnetic medium surface, revolving to the non-magnetic area. The magnetic particle would be put into the concentrate tank, and the non-magnetic material goes into the tailing tank along the lower magnetic yoke gap.

Compared with the flat ring rotary pattern, vertical ring moving direction is opposed to the concentrate ore discharging direction. This design could avoid the big particle size blocking in the gap of the magnetic medium, and it would be put into the tailing tank. The problem of blocking of the high gradient magnetic separation is solved.

1. pulse mechanism; 2. excitation coil; 3. yoke; 4. swivels; 5. feed bucket; 6. rinsing bucket; 7. concentrate flushing device: 8.: 9. ore concentrate hopper bucket; 10 tailings bucket; 11. level gauge; 12. swivel drive; 13. frame;F.ore feeding; W.fresh water; C. Concentrate. M. Middlings; T.Tailings

Figure2.separation process

Specification of high gradient magnetic separator

| Model | Dia.of revolving ring(mm) | Feeding size(mm) | Capacity (t/h) | Rated background field intensity (T) | Power (Kw) | Water pressure (Mpa) | Weight (T) | Overall dimension(mm) (L×W×H) |

| LHGC500 | 500 | <1.3 | 0.1-0.5 | 1.0-1.8 | 13-48 | 0.1-0.2 | 1.5 | 1800×1400×1320 |

| LHGC750 | 750 | <1.3 | 0.5-1.0 | 1.0-1.8 | 17-48 | 0.1-0.2 | 3 | 2000×1360×1680 |

| LHGC1000 | 1000 | <1.3 | 3.5-7.5 | 1.0-1.8 | 18-39 | 0.2-0.4 | 6 | 2700×2000×2400 |

| LHGC1250 | 1250 | <1.3 | 10-20 | 1.0-1.8 | 25-63 | 0.2-0.4 | 14 | 3200×2340×2700 |

| LHGC1500 | 1500 | <1.3 | 20-30 | 1.0-1.8 | 31-48 | 0.2-0.4 | 20 | 3600×2900×3200 |

| LHGC1750 | 1750 | <1.3 | 30-50 | 1.0-1.8 | 39-54 | 0.2-0.4 | 35 | 3900×3300×3800 |

| LHGC2000 | 2000 | <1.3 | 50-80 | 1.0-1.8 | 43-133 | 0.2-0.4 | 50 | 4200×3550×4200 |

| LHGC2500 | 2500 | <1.3 | 80-150 | 1.0-1.8 | 62-100 | 0.2-0.4 | 78 | 5800×5000×5400 |

| LHGC3000 | 3000 | <1.3 | 150-250 | 1.0-1.8 | 72-211 | 0.2-0.4 | 132 | 7600×6500×7200 |

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087