This paper introduces an automatic production technology of

silica sand processing plant, that is, the automatic production system of natural quartz sand and its automatic control method.

Natural quartz sand is a kind of hard, wear-resistant and chemically stable silicate mineral. Its main mineral composition is silica. The color of natural quartz sand is milky white, light yellow, brown, gray or colorless and translucent, and its relative density is 2.65. Its chemical, thermal and mechanical properties have obvious anisotropy. It is insoluble in acid and melting point is about 1750 centigrade. It has high fire resistance. Natural quartz sand has unique physical and chemical properties, especially its intrinsic molecular chain structure, crystal shape and lattice change law. It has high temperature resistance, small thermal expansion coefficient, high insulation, corrosion resistance, piezoelectric effect, resonance effect and its unique optical properties, which play an increasingly important role in many products. Major uses: 1. Manufacturing glass, can produce flat glass, float glass, glass products, optical glass, glass fibers, glass instruments, conductive glass, glass cloth and anti-radiation special glass; 2. Used in ceramics and refractories, such as ceramic embryo and glaze, kiln furnace high silicon brick, ordinary silicon brick and silicon carbide; 3. Used in metallurgy, such as silicon metal, ferrosilicon alloy and silicon-aluminium alloy; 4. Buildings, such as concrete, cementitious materials, road building materials, artificial marble, cement physical performance testing materials, etc. 5. Chemical industry, such as raw materials of silica compounds and sodium silicate, fillers of sulfuric acid tower, amorphous silica powder; 6. Transaction machinery, such as the main raw materials of casting sand, grinding materials, etc.

This paper deals with the preparation of a natural

quartz sand. Its appearance is colorless and translucent. Its characteristics are that the content of SiO2 is over 98% and the particle size of the product is 1-1.2mm. It is mainly used for making glass, refractory, abrasive material, casting quartz sand. It can also be used for making acid-resistant concrete and acid-resistant mortar in construction. The raw material for producing natural quartz sand is natural quartz stone. Natural quartz stone is a kind of silicate mineral with hard texture, abrasion resistance and stable chemical properties. It is processed by washing, crushing, acid treatment, washing and drying with natural quartz stone as raw material. It can produce natural quartz sand with good quality in batches.

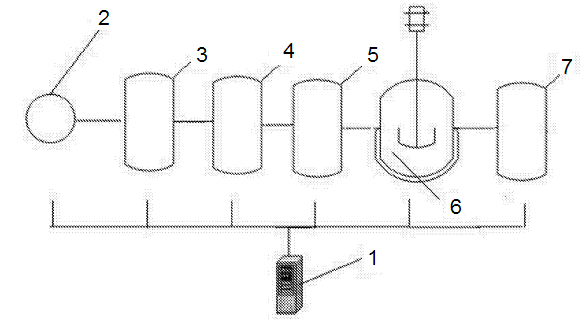

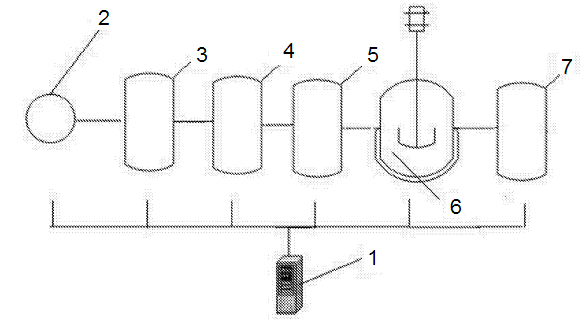

The following is the frame diagram of the automatic production system of natural quartz sand.

1.processor, 2.pump, 3.feeder, 4.peeler, 5.

rod mill, 6.

pickling equipment, 7.

silica sand dryer

The whole production system is collected and controlled by a processor with a PID controller (PLC). The temperature and pressure tester automatically adjusts the parameters of the PID controller to control the feed regulating valve on the feed pipe to achieve small inertia action, so as to control the amount of raw materials in the washing machine; or the control valve in the pickling pool is automatically adjusted by the PLC to adjust the amount of acid to make the pickling. The temperature in the pond is stable. The natural quartz stone is ground into 1-1.2mm objective particles by a rod mill. The grinding time is 12-14 hours. The concentration of dilute hydrochloric acid in the pickling equipment is controlled by automatic adjustment of PLC, which is 25%-30%. The pickling time is 12-24 hours. The natural quartz sand after pickling is washed and dried in the washing pool. The drying temperature is 45-55centigrade and the drying time is 12 hours.

Comment: The control system of silica sand processing plant needs to be adjusted according to the specific production process to better serve the normal and good operation of the whole quartz sand production line.