SINONINE glass sand washing plant is is to produce ultra-white Photovoltaic glass quartz sand and float glass quartz sand,The particle size and chemical composition requirements of two kinds of glass quartz sand are as follows:

| Item | SiO2(%) | Fe2O3(%) | Al2O3(%) | Size |

| Photovoltaic glass quartz sand | >99.5 | <0.01 | <0.3 | 0.1-0.6mm>90% |

| Float glass quartz sand | >98.5 | <0.08 | <0.8 | 0.125-0.71mm>90% |

The requirements for raw materials to produce glass quartz sand

There are two main raw materials for producing glass quartz sand, one is lump quartz stone, the other is natural granular silica sand, two kinds of raw materials through a series of processing technology, can produce glass sand to meet the requirements.

Processing flow of glass quartz sand

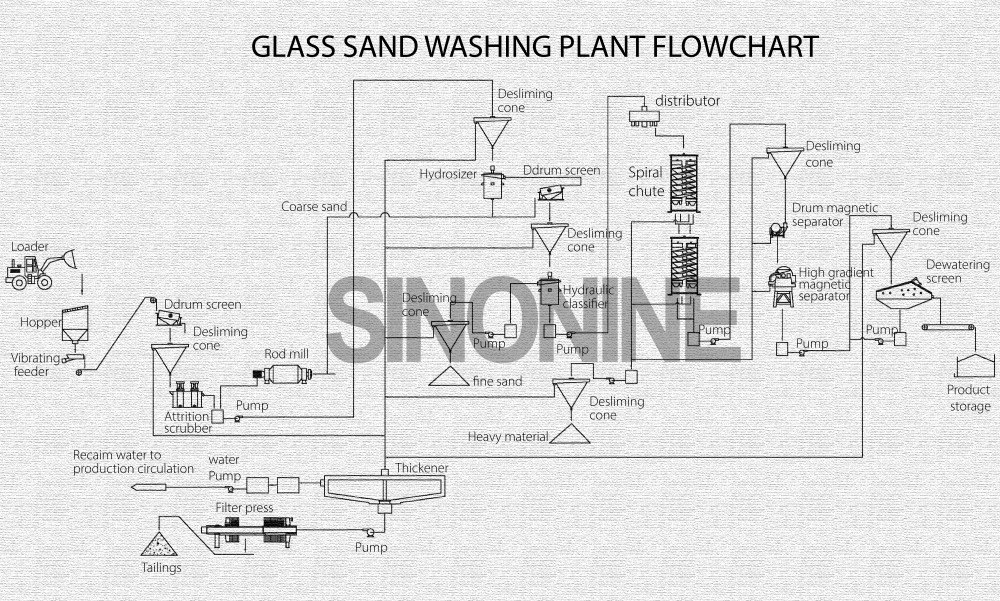

The quartz sand processing flow should go through all or part of crushing - screening - grinding - classifying - scrubbing - desliming - gravity separation - magnetic separation - flotation - dewatering. If the raw material is granular silica sand, there is no need for crushing and grinding, and it can be directly sent into the subsequent production process. The main purpose of quartz sand processing is to remove clay and other impurities, improve the content of quartz sand, reduce the content of Fe2O3 and impurities, and control the particle size in a certain range. Different raw materials, the use of processing technology will be different, typical glass sand production processing flow is shown as the following figure.

Crushing &grinding

The lump quartz stone should be crushed into<20mm particle size by jaw crusher and cone crusher, and then into the rod mill for grinding, the ground quartz sand sent to the classifying system. If the raw material is granular silica sand, it can be directly entered into the classifying system after screening.

Cassification

After grinding, the sand slurry enters the hindered settling machine to separate the coarse sand to return to the rod mill for regrinding, and the overflow enters the hydraulic classifier to separate the fine sand. In this way, the sand is separated out of a certain size range through hindered settling machine and hydraulic classifier, and then it can enter the next step of scrubbing and desliming system.

Scrubbing & desliming

The classified quartz sand enters the forced scrubbing machine to fully dissociate the impurities covered on the surface of the quartz sand, effectively removing the residual clay and impurities, and effectively removing the iron oxide material wrapped on the surface of the sand particles.

Magnetic separation

After scrubbing the iron material in sand shall be removed through the magnetic separation system. firstly using magnetic separator with medium magnetic field intensity to remove strong magnetic iron material, and then use high magnetic field intensity magnetic separator to remove weak magnetic iron material. Remove as much iron material as possible from the quartz sand.

Flotation

In order to further improve the content of SiO2 and reduce the content of iron, the grade and quality of quartz sand should be further improved by flotation. Using quartz sand flotation machine, adding appropriate reagents, the residual impurities and iron material in the quartz sand are removed to obtain high quality glass quartz sand

In addition to the above processing technology, acid scrubbing, leaching or pickling, gravity separation and other processes should be arranged according to the situation of raw materials to remove residual iron materials and heavy minerals, so that the final product meets the requirements.

Sinonine's glass sand production line is of cost-effective and the world's advanced level, which can make full use of the quartz sand raw materials, and will take appropriate processes to produce the best glass sand products according to the quality of the raw materials.The Sinonine glass sand production line can meet the production capacity of 30-500tph, from lab-scale test, design, equipment manufacturing to the final production line installation guidance,trial run and commissioning, Sinonine can provide a full range of services on a turnkey basis.

+86-25-58875679

+86-25-58875679 +86-18118821087

+86-18118821087