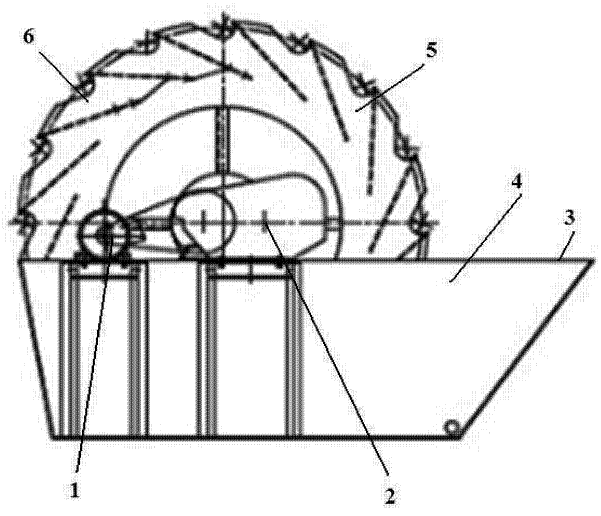

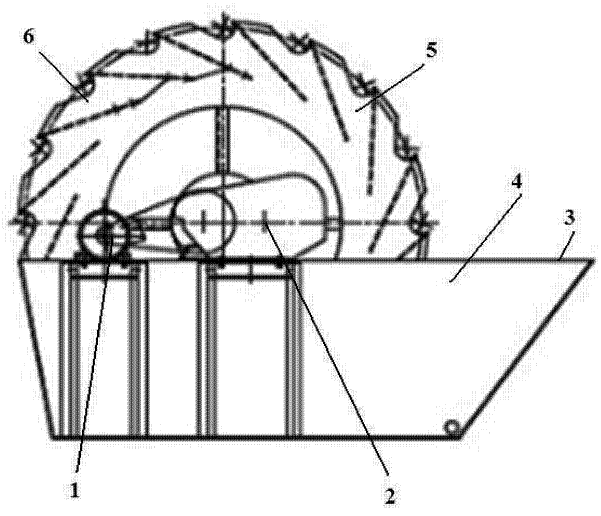

Recently, sinonine has improved the structure of

wheel sand washing machine, making the equipment more perfect.

Wheel sand washing machine is a washing equipment for processing sand and slag particles. This

sand washing machine is used to wash the sand by flowing water. The artificial sand will generally contain certain impurities and dust after being crushed. As a product directly, it cannot meet the relevant industry standards, so the washing machine becomes an indispensable stage in the sand processing plant.

The shape of the wheel sand washing machine is similar to that of the waterwheel, and the flow mode is similar to that of the waterwheel. The sand produced flows in from one side and is discharged from the other side after rotating the wheel bucket for one circle. The water is injected from one side and automatically overflows to one side, so as to ensure the purity and cleaning capacity of the water. The speed of the existing impeller sand washing machine is fixed, which can not wash the sand with different particle size and impurity content at the best speed, resulting in energy waste. To solve this problem, sinonine has improved its structure.

A motor is installed on the sand washing tank of the wheel sand washing machine. The motor is connected to the reducer through a belt, and the reducer is connected to the wheel shaft through a transmission shaft. The impeller is installed on the impeller shaft, and the impeller rotates for sand washing.

The sand washing tank of the wheel sand washing machine is square. The tank plate at the inlet of the sand washing tank is inclined 45 ° outward, the front and rear tank plates of the sand washing tank are vertical upward, the tank plate at the outlet is inclined outward, the inner side of the tank plate is provided with anti-corrosion and anti rust coating, the tank plate is thickened, and the bottom is provided with a drain hole.

The impeller of the sand washing machine is cylindrical, the outer wall of the impeller has a long strip opening in the length direction, the center of the impeller is hollow, the outer wall is inclined and installed with a filter screen, the impeller is connected with the impeller shaft through radial spokes, the two ends of the impeller shaft are connected with the sand washing pool through bearings, and the bearings and impeller shafts are higher than the sand washing tank.

The reducer of the wheel sand washing machine is equipped with a large speed ratio reduction gear set. The speed change mechanism of the reducer is a two shaft speed change mechanism. The input shaft and output shaft of the reducer are set at the same end. The output shaft of the reducer is connected with the impeller shaft through the coupling. The reducer is a three speed change, which is installed on the sand washing tank through the frame.

By setting the reduction gearbox and increasing the torque, the smoothness of cleaning can be improved.

By setting a speed reducer to adjust the speed, it can adapt to the sand and stone of different particle size and different impurity components, and clean with the best efficiency to reduce energy waste.

1.Motor, 2. Reducer, 3. Feeding port, 4. Sand washing tank, 5.Impeller, 6. Discharge port

Sinonine is professional in all kinds of sand washing equipment and can provide all kinds of sand washing solutions.