Sinonine develops a new type of

sand washing machine, which combines sand washing and dewatering to form a complete set of sand washing and dewatering system.

Recently, the requirement of sand for construction industry has been improved. The requirement of sand mainly includes the content of mud and other harmful impurities, such as salt alkali and other corrosive steel bars, which affect the life of buildings. Therefore, it is a more effective method to clean the soil and harmful impurities in the sand with a sand washing machine.

The existing sand washing machine rotates slowly through the impeller, the sand and stone roll in the sand washing tank driven by the wheel bucket, and grind each other to remove the impurities covering the surface of the sand and stone, while destroying the water vapor layer covering the sand; at the same time, add water to form a strong water flow, timely take away the impurities and the impurities with small specific gravity, and discharge from the overflow outlet washing tank to complete the sand and stone discharge function. In the process of sand washing, the sand containing mud powder cannot be cleaned, and the sand loss is serious in the process of sand washing. At the same time, the washed sand will take away a lot of water, resulting in waste of water resources.

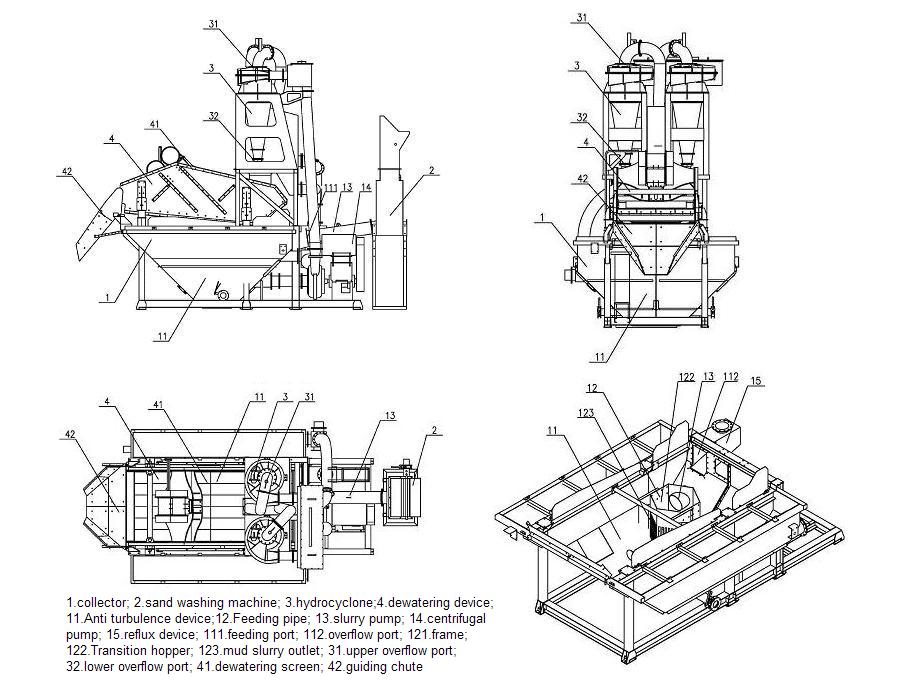

In order to overcome the shortcomings of the existing technology, Sinonine has developed a new type of sand washing machine and method, which can meet the requirements of the construction industry in the sand washing process, further improve the recovery rate of fine sand and save water resources. The sand washing machine is a sand washing and dewatering machine, which includes sand washing machine, dewatering screen, driving mechanism and driving mechanism. The output end of the sand washing machine is connected with the inlet of the dewatering screen, the other end of the dewatering screen is the outlet, the upper part of the dewatering screen is provided with a vibration motor, and the lower part of the dewatering screen is provided with a recovery tank, which is characterized by: the upper part of the dewatering screen is also provided with a secondary recovery tank, the recovery tank is connected with a water pumping pipe and a water pump, the output end of the water pump is connected with the inlet of the hydrocyclone located at the upper part of the dewatering screen through a water supply pipe, and the hydrocyclone The overflow port is connected with the secondary recovery tank, and the sand settling port at the lower part of the hydrocyclone is connected with the dewatering screen. During the operation of the sand washing machine, the sediment is cleaned by the cleaning device and then sent to the cleaning tank by the feed pipe, and the slurry in the cleaning tank is sent to the dehydration device by the centrifugal pump.

The cleaning device of the sand washing machine includes a support frame, an upper cleaning tank and a lower cleaning tank arranged on the support frame, which are internally connected with the lower cleaning tank; the upper cleaning tank includes a feeding port arranged on the upper end of the upper cleaning tank body, a guide plate arranged under the feeding port, and a washing pipe arranged between the feeding port and the guide plate, on which there are several water outlets facing the guide plate Nozzle: the lower cleaning tank includes a material outlet arranged at the lower end of the lower cleaning tank body and an inlet pipe arranged in the lower cleaning tank, and the inlet pipe is provided with a water outlet for water injection into the lower cleaning tank. The upper cleaning tank and the lower cleaning tank can rise and fall along the vertical direction of the bracket. The water inlet pipe of the lower cleaning tank is equipped with a valve for controlling the water inlet flow, and the lower end of the lower cleaning tank is provided with a sealing cleaning port. The cleaning tank is provided with an anti turbulence device, and the connecting end of the feeding pipe and the sand washing tank extends into the anti turbulence device. The anti turbulence device includes a support and a transition hopper connected to the support, the transition hopper is surrounded by a plurality of bending plates, and the transition hopper is arranged orderly with a plurality of mud outlets.

The dewatering device of the sand washing device includes a

dewatering screen and a guide chute, the swirl separation is connected with the cleaning chute for desliming the mud in the cleaning chute, the swirl separation device is provided with an upper overflow port for discharging waste water and a lower overflow port for discharging large particles of fine sand, the lower overflow port is connected with the feed port of the dewatering screen, and the discharge port of the dewatering screen is connected with the guide chute. The cleaning tank is provided with an overflow port and a return flow device, the overflow port and the hydrocyclone separation device are connected into the return flow device, and the return flow device is provided with a valve for connecting and breaking the overflow port, the upper overflow port and the cleaning tank.

The working process of the sand washing and dewatering machine is as follows: the sand to be washed is sent to the cleaning device, and the impurities such as mud and salt alkali attached to the sand surface are removed through the cleaning device, so as to complete the preliminary cleaning of the sand; the sediment after the preliminary cleaning is sent to the collection device through the feed pipe; the sediment enters the cleaning residue to form the mud, which is sent to the cyclone separation device for desliming, and the fine sand with larger particles is sent to the cyclone separation device for desliming It is sent to the dehydration unit, which dehydrates the cleaned sand and then discharges it.

The machine has the advantages of simple structure, convenient operation and low production cost. The materials are cleaned by cleaning device, collection device, cyclone separation device and dehydration device in turn. Through the cleaning device, the materials before entering the collection device are removed from the dirt, salt, alkali and other impurities attached to the sand surface, so as to improve the cleaning efficiency; through the hydrocyclone separation device, the recovery rate of fine sand is high; the sand after washing is effectively dehydrated and the treatment effect is good by using the dehydration screen.

Comment: The reasonable sand washing device can not only improve the quality of sand, but also prevent the loss of fine sand and improve economic benefits.