This paper introduces the wastewater treatment system of

quartz sand pickling processing in details. By using this method, the wastewater from quartz sand pickling can reach the discharge standard and protect the environment from pollution.

The main purpose of quartz sand pickling is to remove the fine impurity minerals embedded on the surface of quartz particles and the iron oxides and hydroxides deposited on the surface of quartz particles. These impurities cannot be removed by

magnetic separation or

flotation because of their insufficient magnetic force or buoyancy. The quartz sand after pickling is the raw material guarantee for the production of high-purity quartz sand, while the high-purity quartz sand is the production of optical fiber. It is the only raw material of high quality quartz glass for communication, electronic industry, semiconductor, solar energy, laser, aerospace and other high-tech fields. The results show that the mixed acid of HF and HCl can remove fine impurity minerals, iron oxides and hydroxides embedded on the surface of quartz particles under certain chemical treatment conditions. Therefore, in the

high purity quartz sand processing, the pickling treatment of quartz sand is one of the essential processes, followed by the treatment of acid containing wastewater, the wastewater treatment does not meet the standards, does not meet the environmental requirements, is unable to obtain the production license.

Therefore, in the high purity quartz sand processing, it is necessary to treat quartz sand with acid sometimes. In addition to fluorine-containing ions or H2SiF6, there are also a small amount of chloride ions in the wastewater. In order to make the production go on smoothly, the waste water must be treated comprehensively.

Sinonine provides a comprehensive treatment method for pickling quartz sand wastewater with comprehensive treatment device The system can continuously and efficiently treat the wastewater from quartz sand pickling plant. After neutralization and filtration, the fresh water obtained from the pickling wastewater can be recycled for production, and the solid waste obtained after drying can be used as raw materials for other industrial production, which can ensure that the whole production process does not discharge the production wastewater and solid waste, and the production process of quartz sand acid pickling plant is completed all in line with environmental protection requirements.

The pickling quartz sand wastewater treatment system includes a trench, a middle pool and a filter device, wherein the filter device includes a frame and a filter cloth arranged in the frame, quartz sand is laid on the filter cloth, and a reservoir is arranged at the lower part of the filter device. At least two groups of neutralization tank, filtering device and water reservoir, each group isolated by valves. The neutralization tank is equipped with a stirring device. The pore diameter of filter cloth is 200-300 mesh, and the thickness of quartz sand is 15-40cm. The water treatment system also includes a lime slurry storage tank, which is connected with the neutralization tank through a hose.

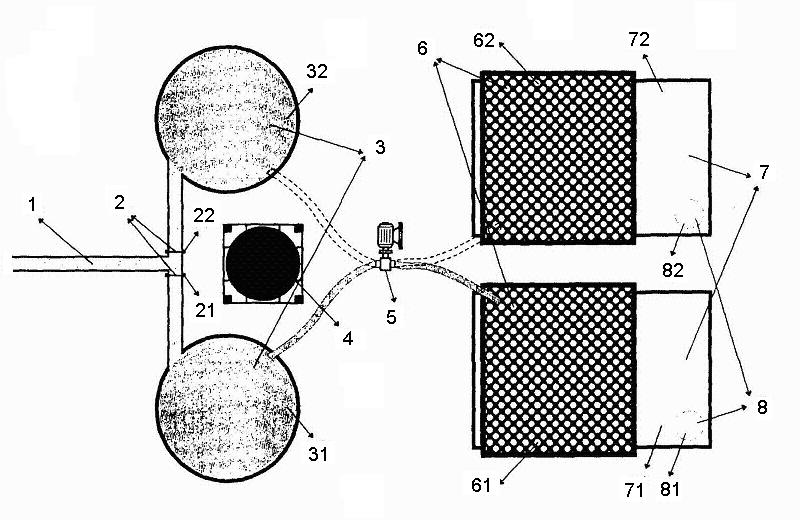

The following figure is the layout plan of the pickling quartz sand wastewater treatment system.

1.Trench, 2.Gate, 3. Neutralization tank, 4.Lime slurry storage tank, 5.Sewage transmission device, 6. Filtration device, 7. Reservoir, 8. Clear water outlet

The waste water from the quartz sand pickling production line is collected into the neutralization tank 31 through the trench 1. At this time, the gate 21 is in the open state and the gate 22 is in the closed state. When the neutralization tank 31 is full of waste water, close the gate 21 and open the gate 22 to make the waste water collected in the trench enter the neutralization tank 32. At this time, open the valve of the lime slurry storage tank 4, add the lime slurry into the neutralization tank 31 through the hose, and open the neutralization tank 31 When the pH value of the wastewater in the neutralization tank 31 reaches 7, close the valve of the lime slurry storage tank 4, close the mixing equipment in the neutralization tank 31, and allow the neutralized wastewater to stand for 2-4 hours. After that, put one end of the hose of the Sewage transmission device 5 into the neutralization tank 3l, connect the other end with the filtration device 61, start the sewage pump of the sewage conveying device 5, transfer the neutralized and flocculated waste water (turbid suspension) in the neutralization tank 31 to the filtration device 61, and filter the waste water (turbid suspension); the solid substances (mainly CaF2 crystal and SiO2 colloid) in the waste water (turbid suspension) is blocked and adsorbed by quartz sand layer, and is retained in quartz sand. Water flows into water reservoir 71 after passing through stainless steel filter cloth, and the clear water stored in water reservoir 71 is connected with production equipment through clear water outlet 81, so that the clean water can be recycled.

As the wastewater in neutralization tank 31 after neutralization and flocculation is filtered, neutralization tank 32 receives the wastewater produced by quartz sand pickling, so the filtration speed must be greater than the wastewater generation speed, so as to ensure that the production wastewater can be treated in time. After the wastewater in neutralization tank 32 is full, neutralization tank 31 can be reused to continue to collect wastewater, and the wastewater in neutralization tank 32 After neutralization and flocculation of wastewater, filter device 61 shall be used to filter the wastewater in neutralization tank 32; filter device 61 shall be used to filter the wastewater after neutralization and flocculation in neutralization tanks 31 and 32 alternately and repeatedly until the filtration speed is obviously reduced, which can not meet the production needs, or the filtration speed is lower than 3 tons / hour. At this time, the hose of sewage transmission device 5 must be connected to the filter device 62, use the filter device 62 to filter, clean the filter device 61, replace the quartz sand layer for backup, and use the drying equipment to dry all the solid substances (including the quartz sand for filtering and the CaF crystal and SiO2 colloid obtained by filtering) as the raw materials of building mortar or facing materials.

For the circulating water stored in the reservoir 71, the CaCl2 concentration must be constantly monitored. When the CaCl2 concentration exceeds 30%, the water becomes high salinity water, which can not be recycled for production. The fresh tap water is used for the quartz sand pickling water, and the filtered clean water is stored in the reservoir 72 for water recycling. The high salinity water in the reservoir 71 is pumped out by the hose through the outlet 81 and transported to the fluidized bed dryer for evaporation and drying, obtaining CaCl2 crystal products for utilization, and cleaning the clean reservoir 71 for standby.

Remarks: wastewater treatment is very important for sand washing plant. It is necessary to plan reasonably in the process of production line construction to realize green production.