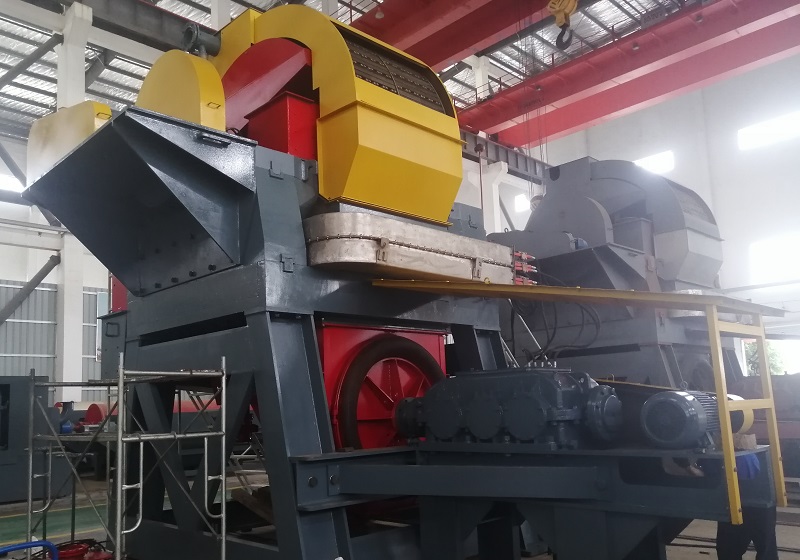

The high gradient magnetic separator (HGMS)is suitable for the ore dressing of weak magnetic minerals, such as hematite, limonite, siderite, ilmenite, chromite, wolframite, tantalum niobium, red mud, etc. The vertical ring high gradient magnetic separator is also very suitable for the removal of iron and purification of nonmetallic minerals. For example: silica sand, feldspar, nepheline, fluorite, silica, spodumene, kaolin, etc., especially in quartz sand washing plant, high gradient magnetic separator plays a key role in iron removal of quartz sand, which can effectively control the final iron content of quartz sand products and ensure the quality of quartz sand.

The vertical high gradient magnetic separator(HGMS) adopts the working mode of vertical rotating ring and recoil concentrate, and is equipped with high frequency vibration mechanism. The vertical ring high gradient magnetic separator has the advantages of large enrichment ratio, strong adaptability to raw ore fluctuation, reliable operation, convenient operation and maintenance, and plays a very important role in the field of mineral processing. The following are the daily maintenance points of the vertical ring high gradient magnetic separator summarized by SINONINE for customers to guide production.

1.Maintenance method of rotating ring bearing of vertical high gradient magnetic separator (HGMS)

The main shaft of the high gradient magnetic separator is equipped with a waterproof clip, which is mainly used to prevent pulp and water from entering the bearing seat house, thus damaging the bearing. Shaft rotation speed is very slow, bearing wear is very small, but need to add grease to each bearing seat once a month for maintenance, bearing can operate normally for many years without replacement.

2.Maintenance of rotating ring transmission gears of vertical high gradient magnetic separator

When installing the gear box, it is necessary to adjust the meshing clearance of large and small gears to prevent the occurrence of gear not stained with oil or tooth root, so that the whole machine can not run smoothly. After the correct installation and commissioning, add enough lubricating oil to the gears regularly every month to ensure the normal operation of the gear. If the maintenance is obtained, the service life of the gear of the vertical high gradient magnetic separator can be as long as many years.

3.Maintenance of pulsating part of vertical ring high gradient magnetic separator

The pulsating parts of the vertical ring high gradient magnetic separator bear the alternating force, plus the slurry pressure, the pulsating part may be exposed. When it is found that the pulsating part has leakage, it should be repaired and adjusted in time. If the loopholes are not repaired in time, the loopholes will expand quickly, causing damage to the machine parts, thus affecting the normal function of the whole machine. The stroke outlet of the pulsating stroke box is easy to enter water, so it should be protected. There is a water baffle above the stroke box and its motor. The stroke box should be supplemented with lubricating oil once every three months, and the cleanliness of the lubricating oil should be maintained at the same time.

4.Maintenance of tailing valve of vertical high gradient magnetic separator

The tailing valve of vertical ring high gradient magnetic separator is one of the parts easy to wear. It has the function of throttling and bearing the pulsating force of pulp. The service life of general industrial valve is 1-3 months. In daily life, 2-3 sets of tailing valves should be prepared. If they are damaged, they should be replaced in time.

In addition to the maintenance of the above important parts, the vertical high gradient magnetic separator in the process of use, to comply with reasonable specifications, according to the specified operating parameters for operation, can not overload operation, to carry out regular overhaul, make it in the best working condition.

For more information and knowledge about vertical ring high gradient magnetic separator, please visit SINONINE website www.9silica.com , or contact us directly + 86-18118821087 (WhatsApp).

The flotation method provided by Sinonine can effectively remove feldspar in quartz sand, which is widely used in quartz sand washing plant and has achieved good results.

Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large production. www.9silica.com, +8618118821087

Raw sand go into silica sand washing plant to become high purity sand.

High-purity quartz powder has excellent optical, thermal, chemical stability and radiation resistance, so it has a wide range of applications in electronic industry, optical communications, military and other fields. With the development of electronic industry, optical communication, laser, optics a

sand washing plant for high purity sand

After drying by fluidized bed dryer system, the moisture content of silica sand can be less than 0.5%, and the moisture distribution is very uniform.

Most of the hydraulic graders in sand washing plants adopt the automatic control system, which has achieved good results.

The processing technology of high purity quartz sand washing plant usually includes complex processes such as calcination, water quenching, classification, magnetic separation, flotation, acid leaching, cleaning and chlorination roasting.

Thank you for your interests in Sinonine, Please feel free to submit your inquiry information to us, our expert will contact with you as soon as possible.