In the

sand washing plant, the traditional quartz sand purification process, the vast majority of gangue minerals and gas-liquid inclusions in quartz raw materials can be dissociated or destroyed to remove, but the removal of lattice impurities is very difficult. After acid leaching, the process has reached the ultimate purification. If the amount of HF is excessively increased, the temperature or the time is prolonged, it can only cause the whole dissolution of quartz minerals, reduce the concentrate yield, and can not purify the impurity elements in the lattice. Therefore, it is necessary to develop a new deep purification process for the purification of quartz with high lattice impurity content.

The main method to remove crystal lattice impurities of quartz sand is chlorination roasting process. Chlorination roasting, also known as chlorination degassing, makes use of the chemical potential gradient on the surface and inside of particles under the action of high concentration of chlorination agent to promote the diffusion of gas-liquid inclusions. There are great differences between different chlorinating agents and lattice impurities.

Different chlorination agents, such as dry hydrogen chloride (HCl), dry chlorine gas (Cl2) and mixed gas of dry chlorine and hydrogen chloride (Cl2 / HCl), were used to purify quartz sand by high temperature chlorination. The results showed that dry HCl, dry Cl2 or mixed gas of dry Cl2 / HCl had obvious purification effect on Na, Fe, K and other metal impurities, and the purification effect of dry HCl was the best;

Chlorination time of 2 h and chlorination temperature of 1000 ℃ are the best for the purification of Na, Fe, K and other impurities in quartz sand;

High temperature chlorination process can reduce the content of Fe, Na and K impurities, but it has no good removal effect on Al.

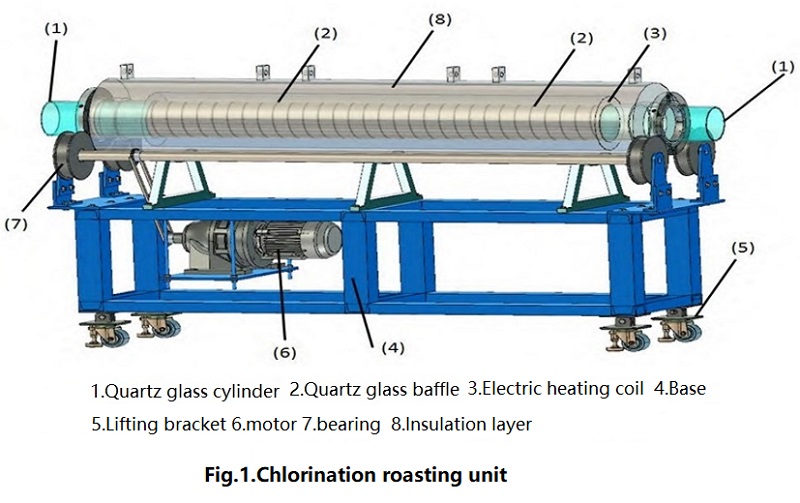

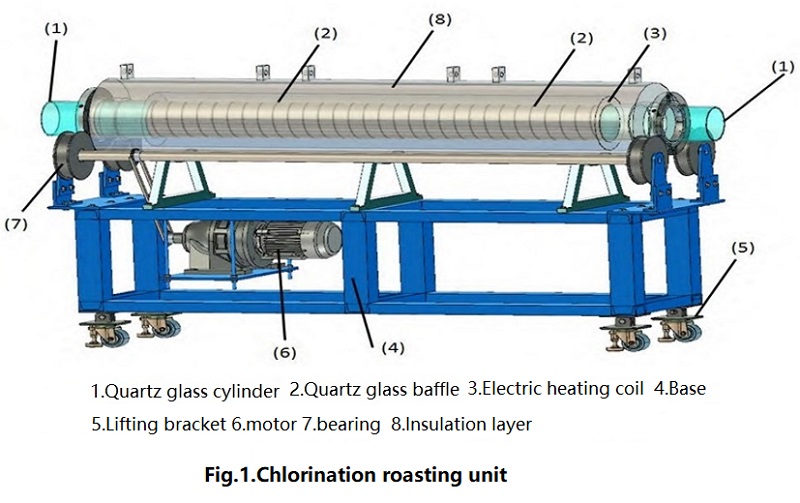

The chlorination roasting unit is as follows

Chlorination purification process of quartz sand

Chlorination purification process of quartz sand

Weigh a certain amount of washed quartz sand and put it into the chlorination roasting device, fill in N2 to exhaust the air, then fill in chlorination agent and mix it with quartz sand evenly, finally raise the temperature to the roasting temperature and keep it for a certain time.

Principle of chlorination purification

The impurities such as alkali metals, alkaline earth metals and residual inclusions on the surface of quartz particles react with hydrogen chloride at high temperature to form gaseous chlorides, which are carried away by high temperature gas flow, so as to achieve the purpose of deep purification.

It should be noted that after high-temperature chlorination, N2 is used to exhaust the roasting tail gas, and the harmful tail gas generated in the chlorination roasting process is absorbed by alkali liquor.

After washing and drying, the mass fraction of Al, Fe, Na and K was analyzed.

In the case of excessive chlorination agent, the temperature and time of chlorination roasting have a key influence on the purification effect.

For information about high purity silica sand processing, please visit Sinonine Website https://www.9ilica.com , or directly us directly by +86-18118821087(whatsapp).