For more information about high purity quartz sand and sand washing plant, please visit https://www.9silica.com , or contact us directly by +86-18118821087(whatsapp).

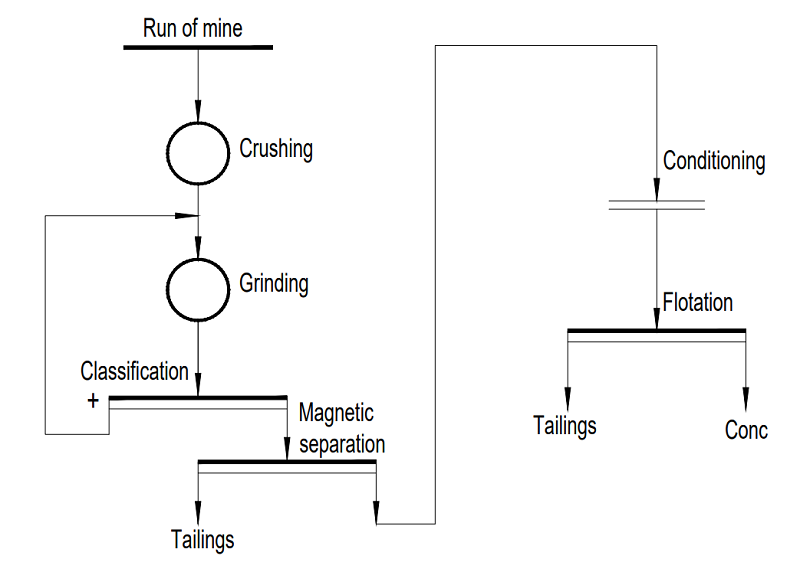

The flotation method provided by Sinonine can effectively remove feldspar in quartz sand, which is widely used in quartz sand washing plant and has achieved good results.

Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large production. www.9silica.com, +8618118821087

Raw sand go into silica sand washing plant to become high purity sand.

High-purity quartz powder has excellent optical, thermal, chemical stability and radiation resistance, so it has a wide range of applications in electronic industry, optical communications, military and other fields. With the development of electronic industry, optical communication, laser, optics a

sand washing plant for high purity sand

After drying by fluidized bed dryer system, the moisture content of silica sand can be less than 0.5%, and the moisture distribution is very uniform.

Most of the hydraulic graders in sand washing plants adopt the automatic control system, which has achieved good results.

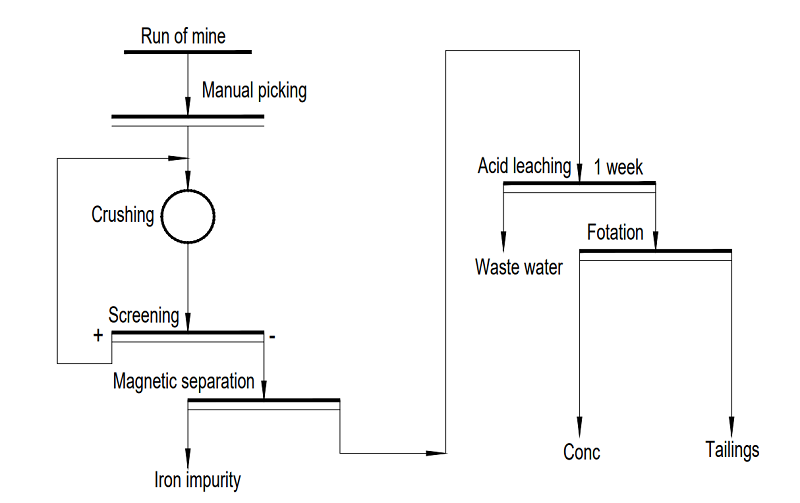

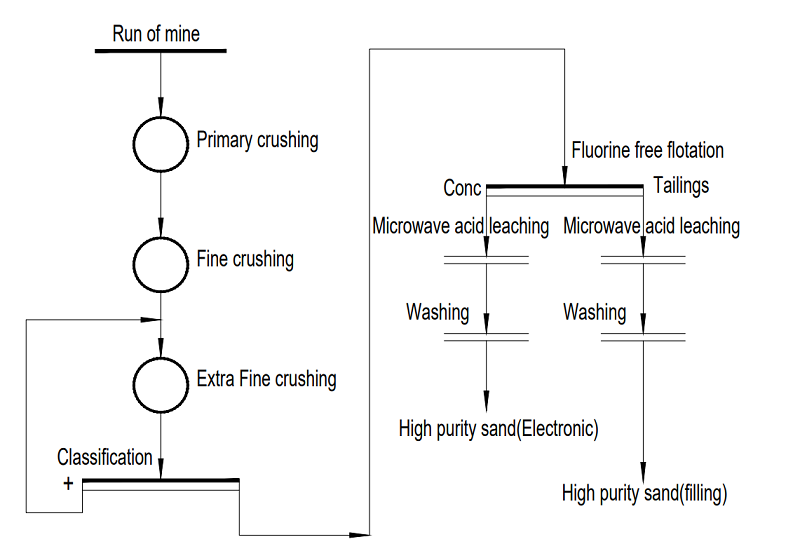

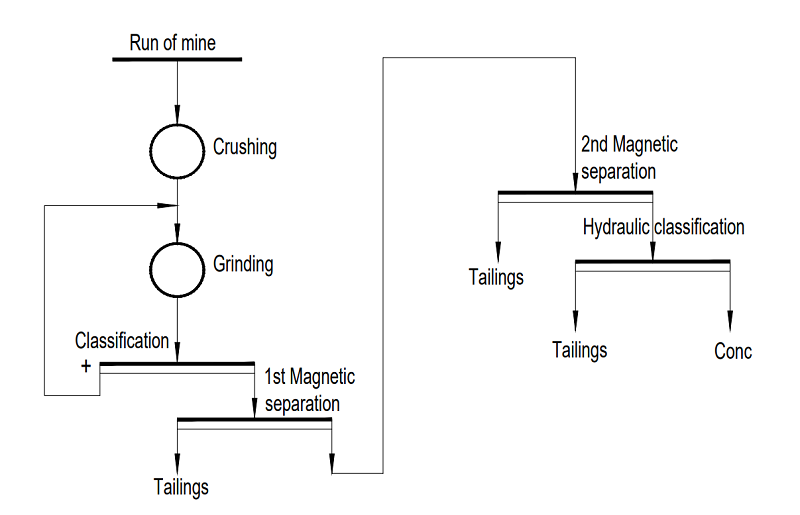

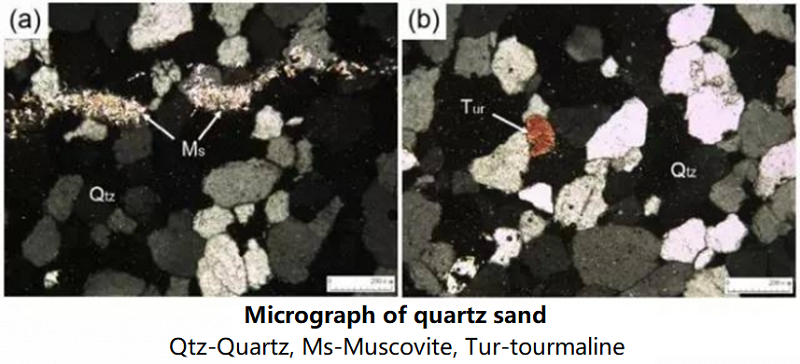

The processing technology of high purity quartz sand washing plant usually includes complex processes such as calcination, water quenching, classification, magnetic separation, flotation, acid leaching, cleaning and chlorination roasting.

Thank you for your interests in Sinonine, Please feel free to submit your inquiry information to us, our expert will contact with you as soon as possible.