Through the unique structure design, Sinonine improves the life of

spiral sand washing machine blades by 100%.

In the field of

silica sand processing and

sand washing plant, the sand washing machine is an indispensable equipment, among which the spiral sand washing machine is the most commonly used equipment. Because of the advantages of low energy consumption, good wear resistance and high quality of sand washing, the spiral sand washing machine is widely used in the cleaning, grading and dewatering links of various ore mining industries. With the motor as the power source, the spiral washing machine drives the spiral shaft to rotate at a constant speed after the reducer is decelerated, and the spiral shaft drives the silt and water flowing into the rear of water tank to mix. The impurities and mud are cleaned, so that the original sand begins to decompose gradually. The separated impurity mud is discharged through the drain pipe under the action of water flow, and the fine sand is transported to the discharge port for discharge under the rotation of the spiral blade, so as to achieve the purpose of sand washing.

In order to prevent the main body of the blade from being damaged by the friction caused by the mixing and conveying of the blade, the outer edge of the spiral blade is provided with a wear-resistant cast iron wear-resistant plate. There are two kinds of wear-resistant plate of old structure, one is connected with spiral blade by two bolts. Because of the uneven surface of the casting itself and the brittleness of the material, the wear-resistant plate is connected with spiral blade by two bolts, which is easy to break due to the incomplete matching of the mating surface. Frequent replacement results in time waste and increased cost. The other is to connect the spiral blade with one bolt, although it is not easy to break, but because only one bolt is fixed, the wear-resistant plate is easy to skew, which can not protect the spiral blade well and affect the appearance.

Through the unique structural design, Sinonine combines the appearance with the actual effect to increase the life of the blade of the spiral sand washing machine by 100%. The specific implementation method is as follows.

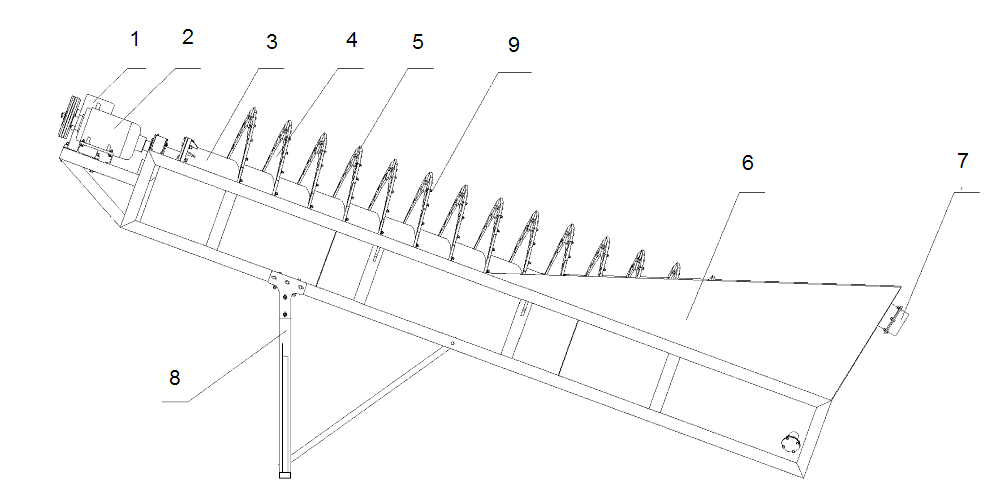

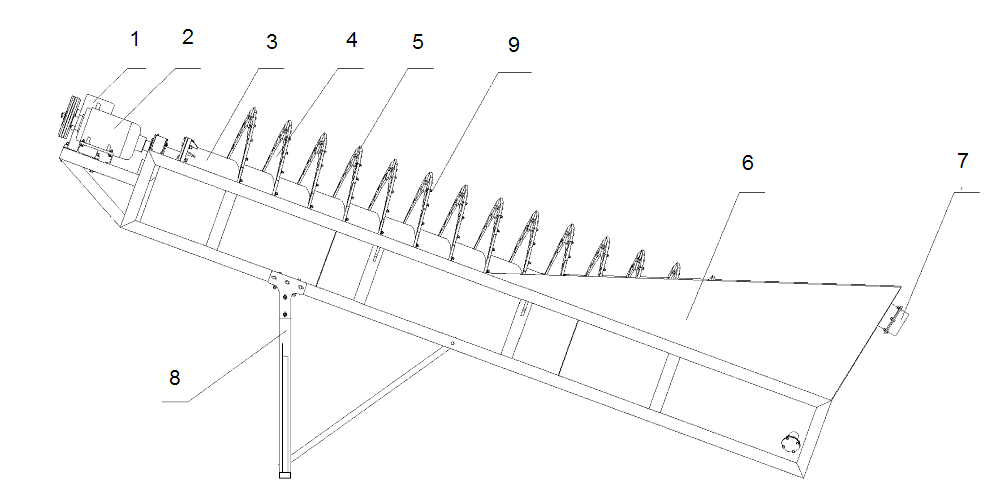

Structure of spiral sand washing machine

The structure of spiral sand washing machine is shown in the figure below.

The spiral sand washing machine is mainly composed of 1. Reducer, 2. Motor, 3. Spiral shaft, 4. Spiral blade, 5. Wear-resistant plate, 6. Tank, 7. Drain pipe, 8. Rack. With motor 2 as the power source, the spiral sand washing machine drives the spiral shaft 3 to rotate at a constant speed after decelerating by reducer 1, and the spiral shaft 3 drives the mud sand and water flowing into the back of tank 6 to mix, clean the impurities and mud, and make the original sand start to decompose gradually. The separated impurity and mud are discharged through drain pipe 7 under the function of water flow, and the fine sand is transported to the discharge port for discharge under the rotation of spiral blade 4.

Wear-resistant plate of spiral sand washing machine

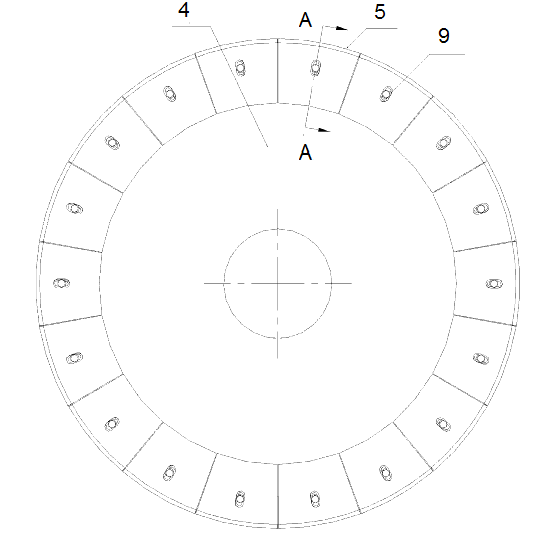

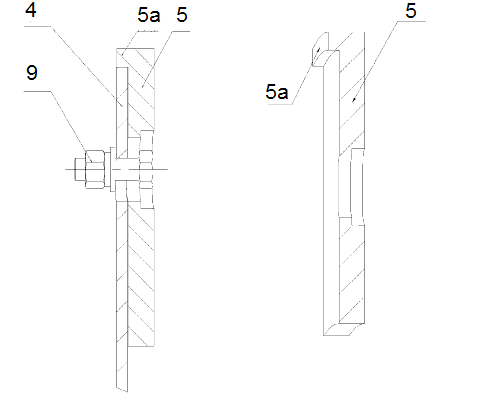

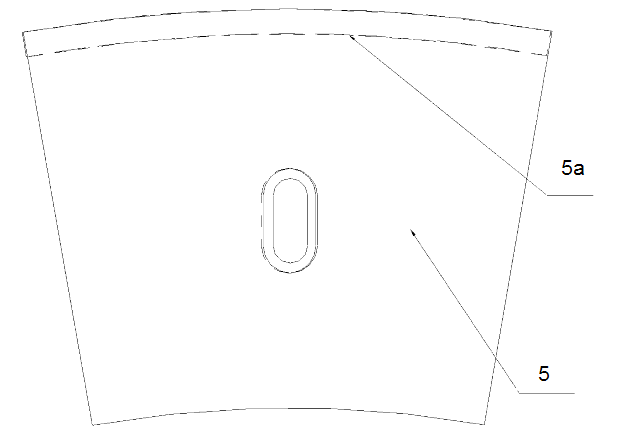

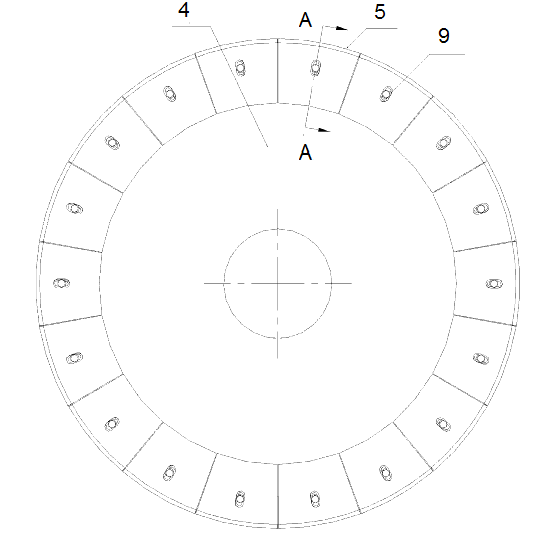

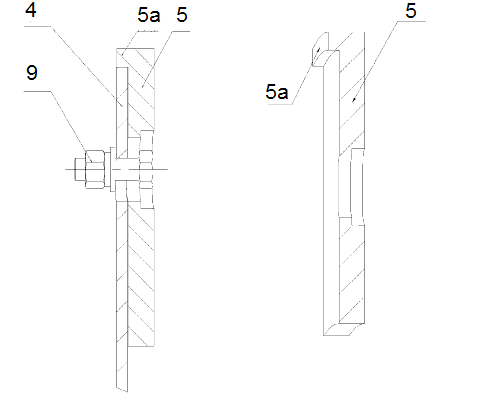

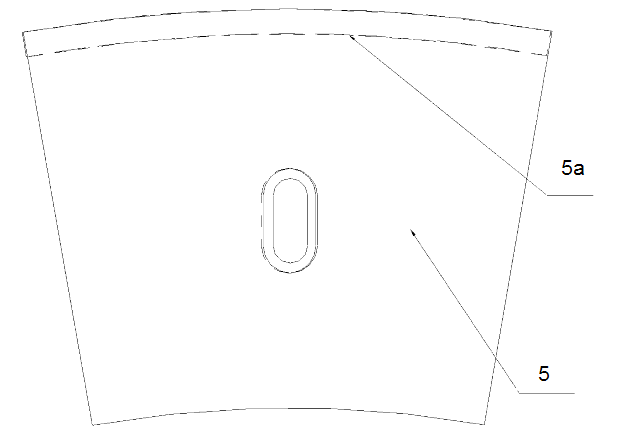

The following figure shows the structure and installation position of wear-resistant plate of new spiral sand washing machine.

Fig1. spiral blade installation drawing

Fig2. Section view of wear-resistant plate

Fig3. Front view of wear-resistant plate

The front view shape of wear-resistant plate 5 is fan-shaped, and the section is L-shaped structure, with L-shaped section retaining edge 5a around the outside of the fan-shaped; the specific installation quantity of the fan-shaped wear-resistant plate 5 varies according to the model, and the size of the fan-shaped is determined by the installation and matching needs of the spiral blade, so as to facilitate the casting production and economy; when the wear-resistant plate 5 is installed, the wear-resistant plate 5 has retaining edge 5a, which is pasted on the spiral blade 4, and the wear-resistant plate retaining edge 5a is close to the spiral blade. On the outer circle of blade 4, fix and tighten the wear-resistant plate and spiral blade 4 with bolt group 9 after the position is determined; the wear-resistant plate 5 is installed on the whole circle of spiral blade 4.

As shown in Fig. 2 and Fig. 3, the installation of the wear-resistant plate of the spiral

sand washing machine includes the spiral blade 4, the wear-resistant plate 5 fixed on the spiral blade and the bolt 9 connecting and fixing the wear-resistant plate and the spiral blade. The section shape of the wear-resistant plate 5 is L-shaped, and the fan-shaped outer circumference of the wear-resistant plate 5 of the plane sector has a retaining edge 5a formed by the L-shaped section, and the retaining edge 5a of the wear-resistant plate is connected and fixed close to the outer circle of the spiral blade 4.

Wear-resistant plate of spiral sand washing machine is simple in structure and easy to install. It is not easy to skew or break in the working process. After long-term runing, it can also be used after the wear of the retaining edge 5a is finished. It only needs to adjust the wear-resistant 5-way spiral blade 4 along the outer diameter through the action of the strip hole and the bolt group 9. The operation is simple and the use cost is reduced. This structure design makes the overall life of the blade of the spiral sand washing machine increase by 100%.

Remarks: This kind of structure can be used not only in spiral sand washing machine, but also in other equipment with spiral device, such as logwasher and spiral ore dewatering machine, which can achieve the same effect.