Sinonine has improved the transmission structure of the

spiral sand washing machine and designed a more reasonable transmission coupling.

Because of the advantages of low energy consumption, good wear resistance and high quality of sand washing, the spiral sand washing machine is widely used in the cleaning, classification and dehydration links of

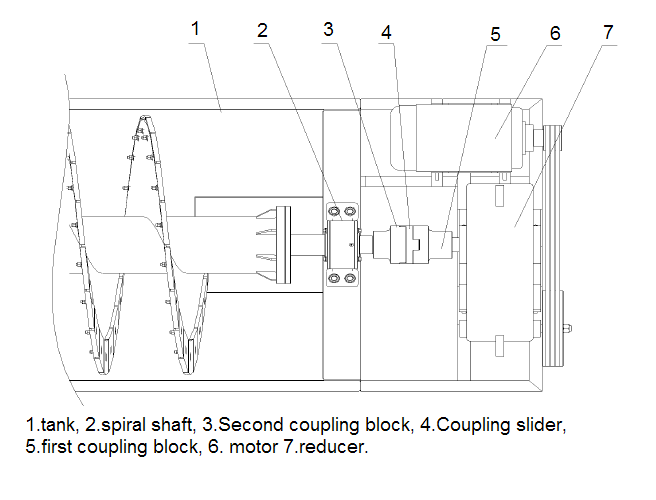

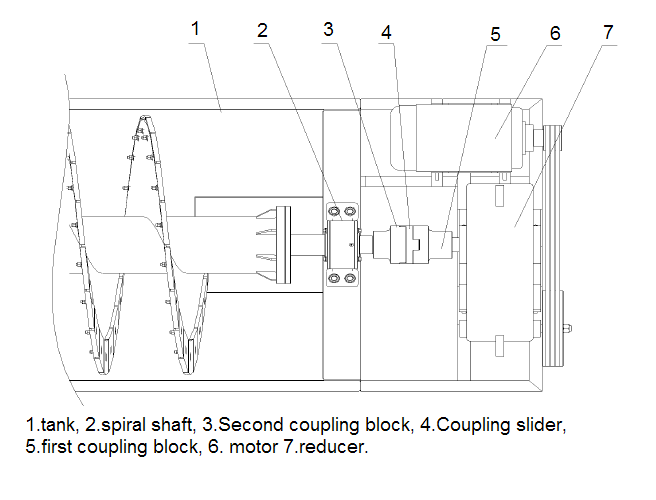

sand washing plant. With the motor as the power source, the spiral washing machine drives the spiral shaft to rotate at a constant speed through the coupling after the reducer is decelerated, and the spiral shaft drives the mud sand and water flowing into the rear of the tank to mix, clean the impurities and mud, and make the original sand start to decompose gradually. The separated impurity mud is discharged through the drain pipe under the action of water flow, and the concentrate sand is transported to the discharge port under the rotation of the spiral blade for discharge, so as to achieve for sand washing purpose.

The standard elastic pin coupling and metal slider coupling are mainly used in the reducer and screw shaft coupling of the traditional spiral sand washing machine. The above two kinds of couplings have large overall dimensions, large weight, high purchase cost, complex installation and inconvenient disassembly.

Through continuous exploration, sinonine has designed a kind of coupling which is easy to install and fix and has low cost. The coupling of the spiral sand washing machine is realized through the following technical routes:

The coupling of the spiral sand washing machine is composed of a coupling block and a connecting slider, which is characterized in that: the coupling block includes a first coupling block with the same structure and connected with the reducer shaft respectively and a second coupling block connected with the spiral shaft; the two opposite sides of the connecting slider are respectively raised, and the two protrusions are perpendicular to each other; the first coupling block and the second coupling block are embedded and connected with the protrusion of the connecting slider through the surface groove. There is a connecting shaft hole on the coupling block, which is connected and fixed with the reducer shaft or spiral shaft. The connection and fixation can adopt interference fit and keyway fixing structure.

The installation steps of the coupling are as follows:

The first coupling block is installed on the output shaft of the reducer, the second coupling block is installed on the spiral shaft; the spiral shaft is assembled on the spiral sand washing box body; the reducer is hoisted to roughly align the output shaft and the spiral shaft of the reducer; the connecting slider is installed into the second coupling block of the spiral shaft; the reducer is assembled to clamp the first coupling block, the connecting block and the second coupling block of the spiral shaft of the reducer; and the coupling block is adjusted properly The coaxiality of the axial device completes the assembly of the main machine.

Suggestion: the transmission system is very important to the stability of the spiral sand washing machine. In the actual operation process, we should pay more attention to its working state.