In the sand making plant and sand washing plant, a large amount of water will be used to clean the clay and impurity in the sand, so as to obtain clean sand. Due to the large amount of sludge and other wastes, the sewage after sand washing needs to be treated before it can meet the requirements of environmental protection. In addition, as water resources are becoming more and more scarce and precious, the treated water can also be returned to the sand washing system for recycling, thus saving water resources and reducing water production costs. Therefore, the treatment of wastewater in sand washing plant is of great significance.

Solution of sewage treatment in sand washing plant

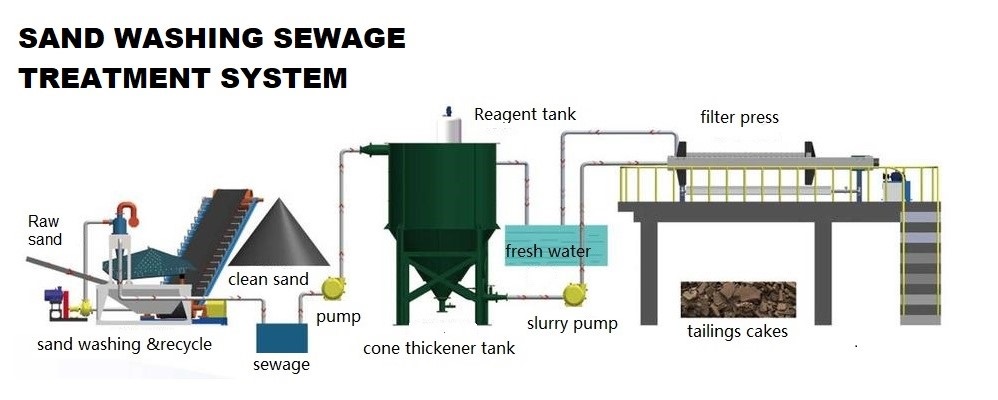

After long-term research and practice, sinonine has developed a set of water treatment system with low price and good effect, which is used for wastewater treatment of sand washing production line. After treatment, the solid and liquid in the wastewater are fully separated, and the solid becomes transportable and discharged as a by-product. The liquid water can be directly discharged or recycled.

The sand washing water treatment system includes two stages: thickening and filtration. Firstly, the waste water from the sand washing plant is put into the thickener tank to add flocculant for rapid concentration, and a large amount of waste water is discharged. After concentration, the solid-liquid mixture enters the high-efficiency filter press to filter the remaining water, making the solid water content reach 15% - 20%, which can be directly transported and discharged.

The water treatment system of the sand washing production line has the following characteristics:

1.High efficiency and energy saving

There is no power in the thickening of the water treatment system. The thickener tank with optimized structure can make the waste water stay in the thickener tank for a short time to achieve the concentration effect. The filter press is powered by the feed pump, without additional energy consumption. The sand washing water treatment system can realize large-scale production and can be used normally with 50-1000tph sand washing production line.

2.Less investment

Different from the traditional water treatment system, the sand washing water treatment system only needs to invest simple equipment to realize large-scale production. The equipment structure is simple, the cost is low, the operation cost is low, the infrastructure construction is less, and the cost can be recovered quickly.

3.Small footprint

Because the sand washing water treatment system adopts the rapid concentration process, the smaller equipment can complete the large-scale production, and the system of the same scale adopts the smaller equipment, and the equipment occupies a small area.

4.Emission standard

The production line is designed according to domestic and international environmental protection standards. The treated wastewater becomes pure solid and clear water, which meets the domestic and international environmental discharge standards and can be used in sand washing production lines all over the world.

In view of the above characteristics, the sand washing wastewater treatment system produced by sinonine has been rapidly popularized and applied with good results. If the water treatment system is used together with the sand washing and fine sand recycle machine produced by sinonine, a complete sand washing production line can be formed.

In the actual production, the sand is cleaned by the sand washing and fine sand recycle machine, and the fine sand is recovered at the same time, and then the water treatment system is used to treat the waste water after sand washing, forming a complete sand washing production solution.

The content of soil and impurities in sand is an important index in the design of water treatment system. Before the design of sand washing wastewater treatment system, it is necessary to clearly understand the content of sand components and design a reasonable system combined with the treatment capacity.

The flotation method provided by Sinonine can effectively remove feldspar in quartz sand, which is widely used in quartz sand washing plant and has achieved good results.

Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large production. www.9silica.com, +8618118821087

Raw sand go into silica sand washing plant to become high purity sand.

High-purity quartz powder has excellent optical, thermal, chemical stability and radiation resistance, so it has a wide range of applications in electronic industry, optical communications, military and other fields. With the development of electronic industry, optical communication, laser, optics a

sand washing plant for high purity sand

After drying by fluidized bed dryer system, the moisture content of silica sand can be less than 0.5%, and the moisture distribution is very uniform.

Most of the hydraulic graders in sand washing plants adopt the automatic control system, which has achieved good results.

The processing technology of high purity quartz sand washing plant usually includes complex processes such as calcination, water quenching, classification, magnetic separation, flotation, acid leaching, cleaning and chlorination roasting.

Thank you for your interests in Sinonine, Please feel free to submit your inquiry information to us, our expert will contact with you as soon as possible.