In the

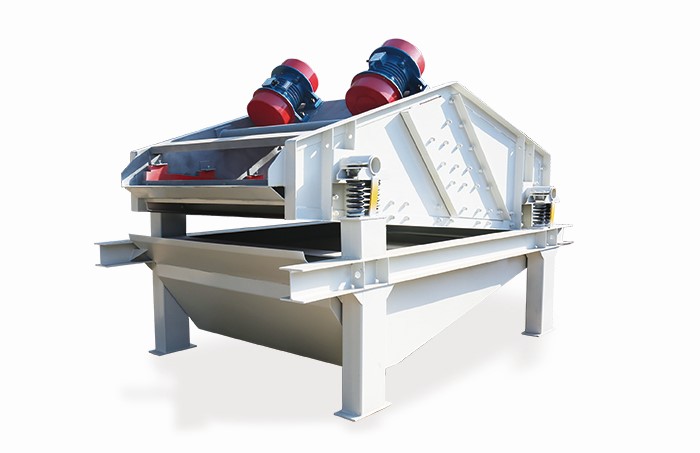

sand washing plant, the dewatering screen uses the mechanical vibration force to achieve the purpose of screening and dewatering, and the vibration force will inevitably damage the machine, improper operation will also cause a variety of failures of the

dewatering screen.

Excessive noise is one of the common faults of dewatering screen, which greatly affects the working efficiency of dewatering screen and the working environment of operators. If the noise problem is not properly solved, the service life of the dewatering screen will also be affected.

How to reduce the noise of dewatering screen? Based on the experience of design and production of dewatering screen, SINONINE summarized several reasons and solutions for excessive noise of dewatering screen as follow.

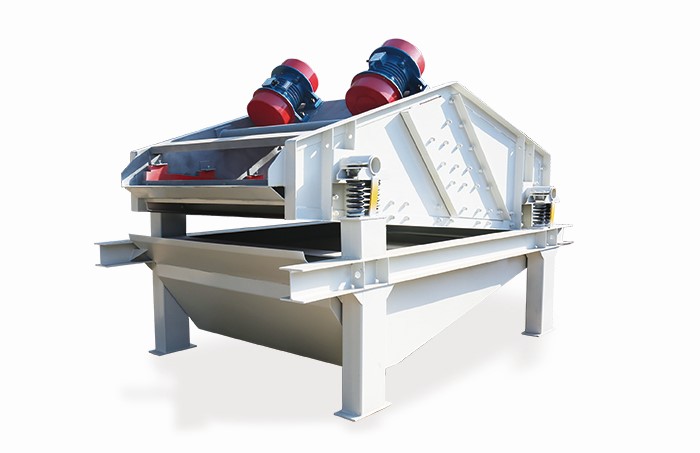

1. The damping spring is loose

The spring of the dewatering screen is connected with the base, so the vibration force of the dewatering screen will be directly transmitted to the damping spring, and the elastic variable of the damping spring is used to buffer and reduce the noise. However, if the damping spring is loose, under the action of vibration force, the spring will produce friction with the base, thus increasing the noise.

Solution: regularly check the tightness of the fixed screw of the damping spring of the dewatering screen. If it is loose, it should be fixed in time.

2. Some bolts are loose

The dewatering screen uses two vibrating motors to work at the same time, so it will produce strong vibration force. Under the action of strong vibration force, each bolt on the dewatering screen will be easy to loosen, causing friction and noise between the screen body and parts of the dewatering screen.

Solution: regularly check the bolt fixation of each part of the dewatering screen, and timely reinforce the bolt if it is found to be loose.

3. The bearing accuracy of vibration motor is not enough or damaged

The vibration source of the dewatering screen is two vibrating motors, and the core of the vibrating motor is the bearing. If the bearing accuracy of the dewatering screen is not enough, the friction between the bearing and the motor will be increased; if the bearing is broken, the friction will be more obvious and the noise will be greater.

Solution: replace the vibration motor with a new qualified bearing

4.Unreasonable selection of dewatering screen mesh

There are many kinds of screen mesh materials for dewatering screen, including polyurethane screen mesh and steel screen. mesh The friction noise of polyurethane screen is lower than that of steel screen. Polyurethane screen should be used as far as possible when the screening effect of dewatering screen is not affected.

Solution: replace the steel screen of dewatering screen with polyurethane screen.

5. The screen body is broken

The capacity of each dewatering screen is limited. The production should be determined according to the capacity of the dewatering screen. If the processing capacity of the dewatering screen is increased due to the tight production task, the load of the dewatering screen will be greatly increased. If the work with high load for a long time will cause the dewatering screen to break. This broken part will produce a large noise when the screen is working.

Solution: reasonably regulate the load of the dewatering screen to avoid the broken of the dewatering screen body.

For more information about dewatering screen and sand washer, please visit SINONINE website www.9silica.com , or contact us directly + 86-18118821087 (WhatsApp).