In

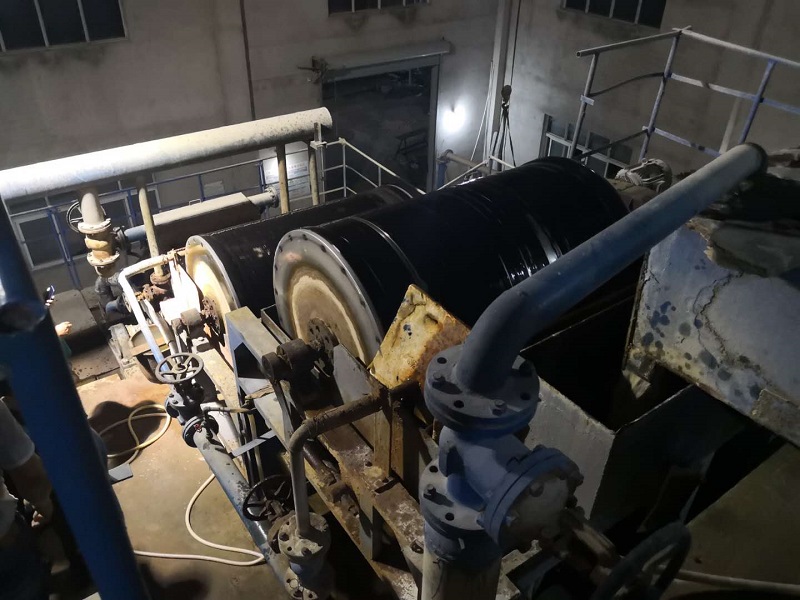

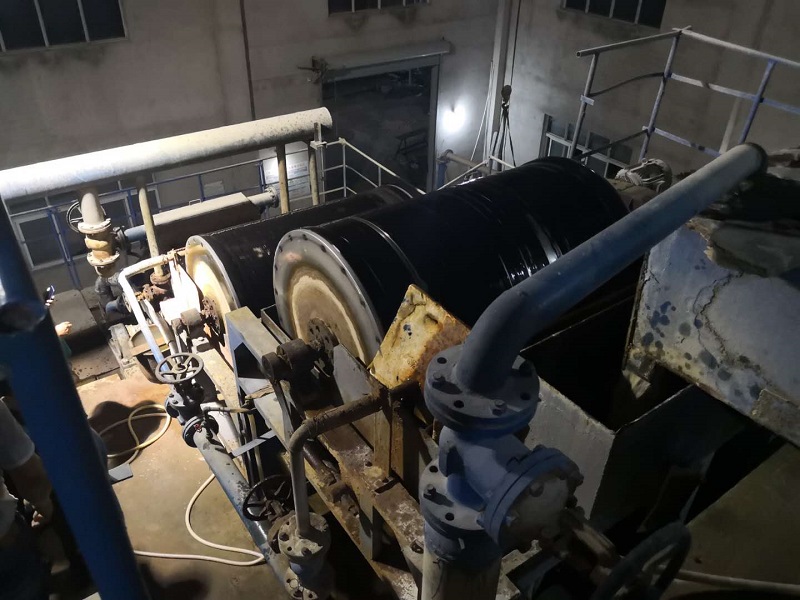

sand washing plant, iron removal is an important process, and iron content is an important index of silica sand quality. The

magnetic separator is an important equipment for iron removal and reduction. The quality and service life of the magnetic separator directly affect the quality and service life of the whole quartz sand production line. The service life of silica sand magnetic separator is not only related to the quality of the equipment itself, but also related to the feed particle size and the technical level of the operator. In order to extend the service life of the silica sand magnetic separator, SINONINE summarizes the following aspects for users' reference.

1. Select high quality silica sand magnetic separator

There are many types of magnetic separator produced in the market. There are great differences in the feed size, output, magnetic separation efficiency and application range of each type. According to the production requirements and the nature of minerals, the high configuration magnetic separator model should be selected to avoid the mismatch between the model and material properties of the magnetic separator, thus affecting the service effect and reducing the service life of the magnetic separator , it is suggested that customers buy magnetic separation equipment from professional manufacturers, with reliable quality and comprehensive technical services. For example, SINONINE is a famous manufacturer of quartz sand magnetic separation mechanism in China. Our magnetic separator include

magnetic drum separator,

High gradient magnetic separator,

Plate magnetic separator etc.

2. Strictly control the grain size of silica sand entering the magnetic separator

The particle size of magnetic separation minerals has an important impact on the service life of magnetic separator. If the particle size is too large, it is easy to cause serious wear to the internal parts of the equipment, thus affecting the quality of the parts, and thus shortening the service life of the whole magnetic separator. In order to reduce the particle size of minerals, users must reasonably design the crushing and grinding process of silica sand, and select the appropriate crusher and grinding machine. To control the size of silica sand into the magnetic separator, meet the performance requirements of the magnetic separator, so as to achieve the best magnetic separation effect.

3. Maintain the magnetic separator regularly

Reasonable maintenance mechanism of magnetic separator shall be specified and silica sand shall be maintained regularly. If necessary maintenance is not carried out, long-term operation will cause serious shortening of service life and performance degradation of equipment. Therefore, the enterprise must send special technicians to carry out regular maintenance of magnetic separator. According to the maintenance specifications of silica sand magnetic separator, regular maintenance, such as lubrication of each lubricating point, tightness of bolts, etc., shall be checked regularly. Meanwhile, the wear of each vulnerable parts shall be paid attention to. If the wearing parts are worn, it is necessary to replace or repair them in time to ensure the normal operation of the equipment and extend its service life.

4. Strengthen the technical training for the operators of silica sand magnetic separator

SINONINE has found that many of the damage of magnetic separator parts is caused by the wrong operation of operators. Therefore, it is very important to strengthen the technical training for operators. Before operating the equipment, operators must understand the structure of silica sand magnetic separator, magnetic separation principle, operation specification, precautions and other aspects of silica sand magnetic separator, master the performance of all aspects of the equipment, and avoid any operation errors.

In addition to the above items, it is also necessary to objectively understand the life cycle of the magnetic separator. For the long-term use of silica sand magnetic separator, all aspects of the performance indicators have decreased significantly. It is also necessary to eliminate it in time, replace the new silica sand magnetic separator, and improve the overall technical level of the sand washing plant.

For more information and knowledge about sand washing plant and silica sand magnetic separator, please visit SINONINE website www.9silica.com , or contact us directly + 86-18118821087 (WhatsApp).