High purity silicon powder has the characteristics of good insulation, low thermal expansion coefficient and high chemical stability. It is widely used in semiconductor raw materials, silicon resin materials, solar cell substrates, optical glass electronic packaging materials, etc. Silicon powder is usually made of natural quartz or fused quartz by crushing, purification, grinding, grading and other processes. It is of great significance to develop and utilize quartz sandstone to prepare high purity silica micro powder by ball milling, scrubbing and magnetic separation.

Analysis of quartz sandstone

The mineral composition and chemical composition of quartz sandstone were analyzed from a place.

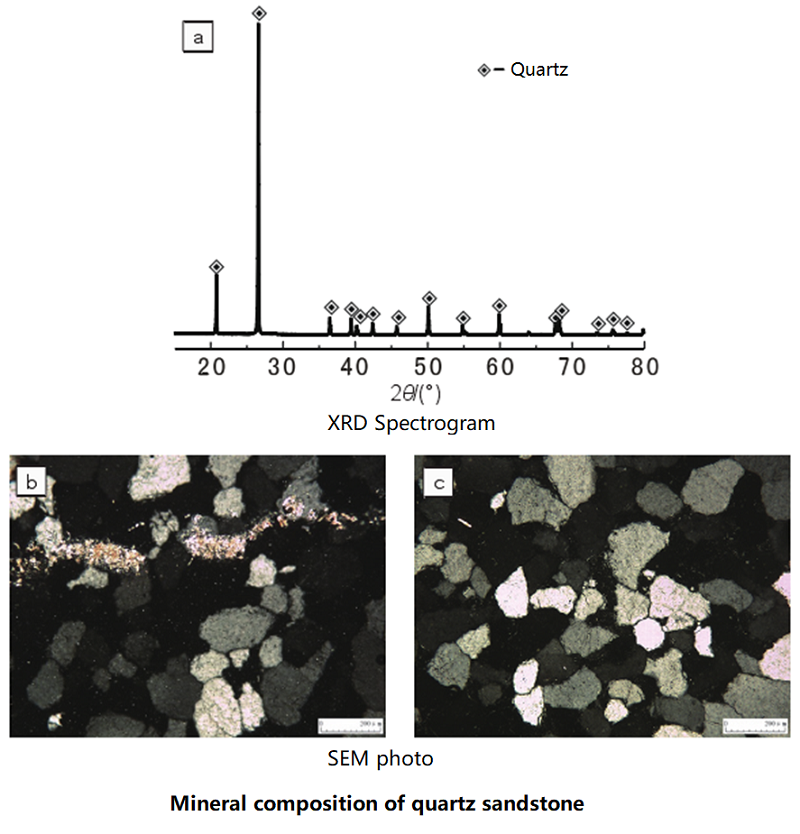

Mineral composition

The volume fraction of single crystal quartz in the quartz sandstone is more than 95%, the sorting roundness is good, the quartz is heteromorphic granular, the particle size is mainly concentrated in the range of 0.05-0.2mm, the fracture is filled with gangue minerals, and there is a small amount of clay matrix between the particles.

Chemical composition

The purity of SiO2 in the quartz sandstone is 99.47%, and the impurities with high content are Al2O3, Fe2O3, TiO2, K2O, Cao and MgO, and the sum of these six impurities reaches 0.0603%.

If the quartz sandstone is used directly, the SiO2 content of the product only reaches the ordinary silicon powder level. Only by reducing the content of other impurities through relevant processes can it be applied to the insulation pouring of electrical components and high voltage electrical appliances, epoxy resin sealing and other industries.

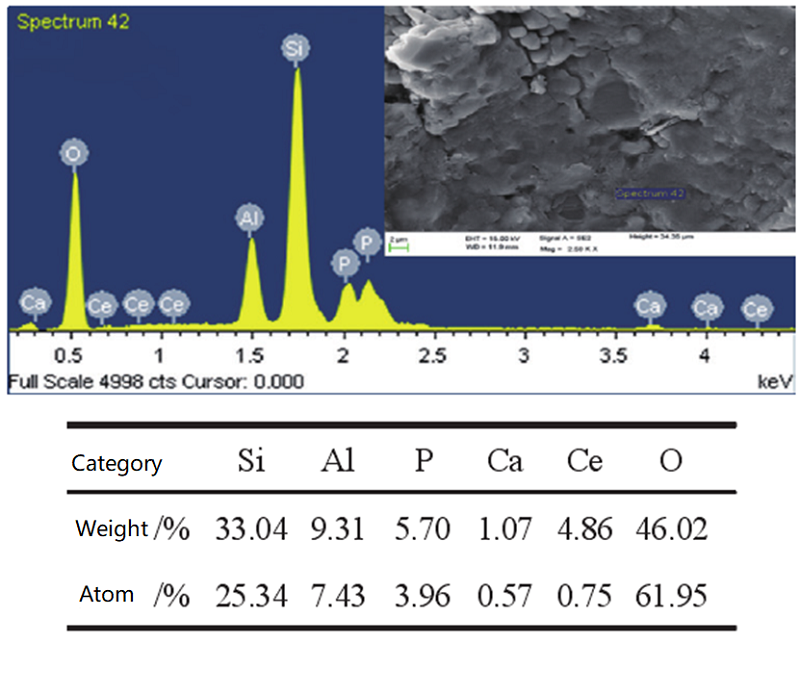

Analysis of micro composition of quartz sandstone

Quartz sandstone is mainly composed of fine quartz grains with the size of 20-30 μ m. The ore contains Al, K, P, CA, CE and other impurity elements, which may occur in phosphate minerals or clay minerals, and can be dissociated from quartz grains by ball milling and scrubbing process.

Preparation of high purity silica powder from quartz sandstone

Process conditions

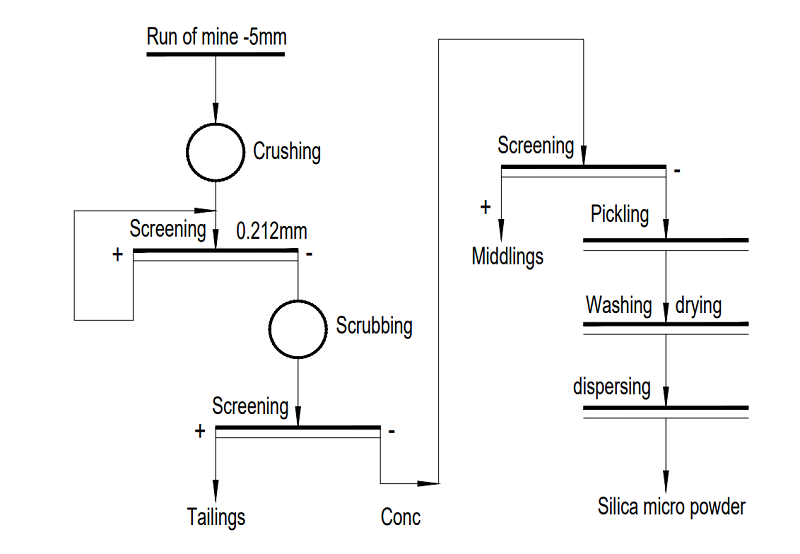

The - 0.212mm quartz sand was obtained by jaw crusher crushing and screening, and the magnetic minerals and impurities in the quartz sand were preliminarily removed by dry high intensity magnetic separator (1.0T).

After ball mill scrubbing and grinding, the quartz sand is ground to a reasonable size, and the iron film and clay minerals on the quartz surface are removed by scrubbing. The ball mill speed is 600r / min, pulp concentration is 50%, grinding time is 80 minutes. The content of SiO2 in fine sand increased to 99.76%, the whiteness increased from 52.7% to 86%, and the content of impurities decreased.

After ball milling and scrubbing, the residual impurities in silica powder need to be treated by acid leaching. The acid content is 12%, the mass ratio of oxalic acid, sulfuric acid and hydrochloric acid is 2.5:3.75:3.75, the liquid-solid ratio is 3ml / g, the temperature is 50 ℃, the ultrasonic acid leaching treatment is 2h, drying and dispersing to obtain high-purity silica powder.

Composition analysis of high purity silicon powder

After crushing, screening, magnetic separation, ball milling, scrubbing and pickling, the high purity silica powder is obtained: SiO2 99.95%, Al2O3 0.0038%, Fe2O3 0.0019%, K2O 0.0008%, TiO2 0.0054%, CaO 0.0024%, MgO 0.0009%, whiteness 87.5%, which can fully meet the requirements of electrical grade silica powder.

There are few raw materials that can directly produce high-purity silica powder, so it is very important to prepare high-purity silica powder from quartz sandstone for the development and utilization of quartz sandstone resources.

For information about high purity silica sand and silica micro powder processing, please visit Sinonine Website https://www.9ilica.com , or directly us directly by +86-18118821087(Whatsapp).

The flotation method provided by Sinonine can effectively remove feldspar in quartz sand, which is widely used in quartz sand washing plant and has achieved good results.

Sinonine high purity silica sand washing plant can work 7x24 hours to Meet the needs of customers in large production. www.9silica.com, +8618118821087

Raw sand go into silica sand washing plant to become high purity sand.

High-purity quartz powder has excellent optical, thermal, chemical stability and radiation resistance, so it has a wide range of applications in electronic industry, optical communications, military and other fields. With the development of electronic industry, optical communication, laser, optics a

sand washing plant for high purity sand

After drying by fluidized bed dryer system, the moisture content of silica sand can be less than 0.5%, and the moisture distribution is very uniform.

Most of the hydraulic graders in sand washing plants adopt the automatic control system, which has achieved good results.

The processing technology of high purity quartz sand washing plant usually includes complex processes such as calcination, water quenching, classification, magnetic separation, flotation, acid leaching, cleaning and chlorination roasting.

Thank you for your interests in Sinonine, Please feel free to submit your inquiry information to us, our expert will contact with you as soon as possible.