In the quartz

sand washing plant, a large amount of wastewater containing acid, high salinity, high chroma and high turbidity will be produced by the pickling purification process, especially the fluoride wastewater, which needs to be properly treated. Quartz sand pickling wastewater generally contains hydrogen ions, fluorine ions, suspended solids, heavy metal ions etc. The difficulty of treatment is how to effectively remove fluorine ions.

Fluorine is an accumulated poison, and plants leaves and grass can absorb fluorine. Cattle and sheep will cause joint swelling, osteoporosis and even paralysis after eating this polluted grass. Excessive fluoride intake will interfere with enzyme activity, destroy the metabolism balance of calcium and phosphorus, and fluorosis with dental plaque and joint deformation. The first level discharge standard of fluoride ion in industrial wastewater is 10mg/l, and the treatment of fluorine containing wastewater is an important environmental protection task.

The following is the

quartz sand pickling wastewater treatment scheme mastered by Sinonine, which has achieved good results.

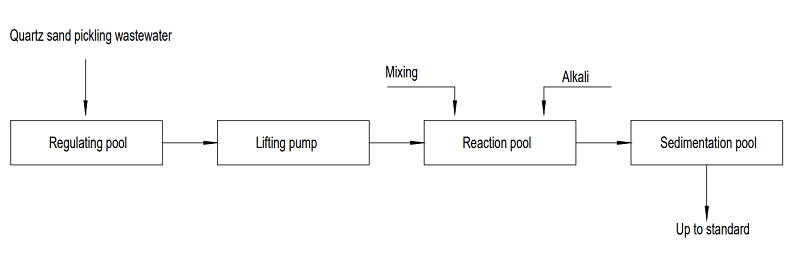

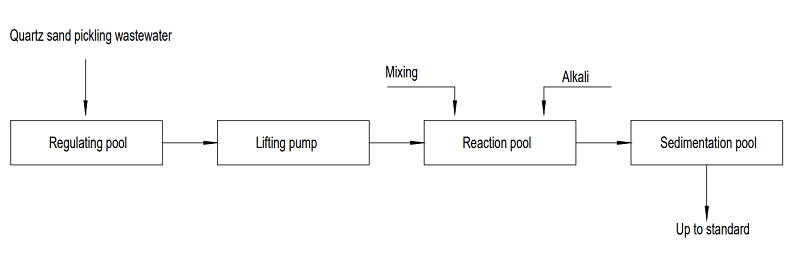

1.Neutralization + Sedimentation process

The waste liquor of quartz sand pickling enters into the regulating tank through the drainage pipe to fully regulate the water quality and quantity of the waste liquor; The adjusted waste water is lifted to the acid-base reaction tank by water pump, and alkaline substances (caustic soda, sodium bicarbonate, lime, etc.) are added to the reaction tank to neutralize with the pickling waste liquid, and the addition and stirring are carried out at the same time. After neutralization of acid and alkali for a period of time, the upper layer of the reaction tank flows into the sedimentation tank freely at night. After sedimentation, the water quality is tested and discharged or recycled after reaching the standard.

Main equipment list

|

No. |

Name |

Qty |

|

1 |

Wastewater regulating pool |

1set |

|

2 |

Acid base reaction pool |

1set |

|

3 |

Lifting pump |

1pcs |

|

4 |

Reagent dosing pump |

1pcs |

|

5 |

Mixer |

1pcs |

|

6 |

Reagent conditioning tank |

1pcs |

|

7 |

PH meter |

1pcs |

|

8 |

Electric control cabinet |

1pcs |

|

9 |

Pipe and cable & hardware |

1each |

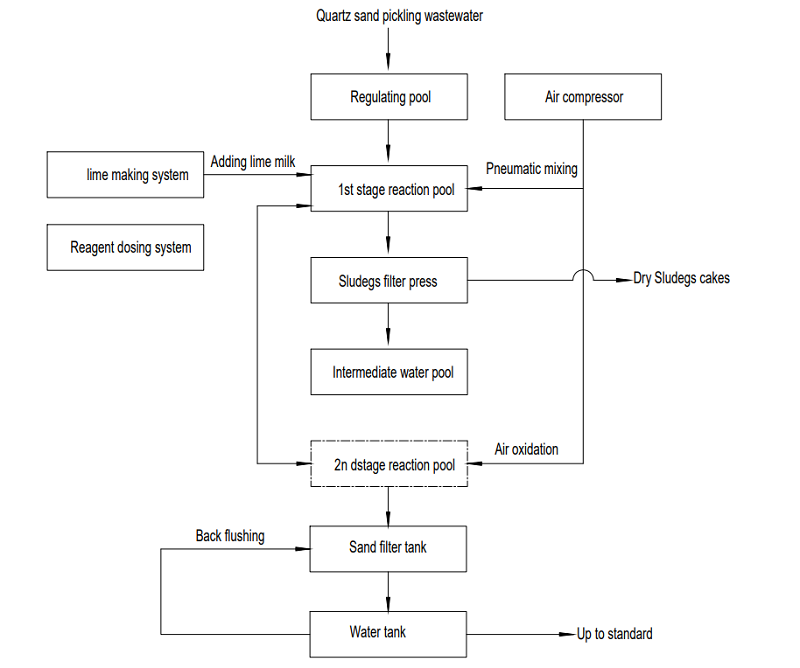

2.Neutralization + sedimentation + flocculant + pressure filtration dewatering process

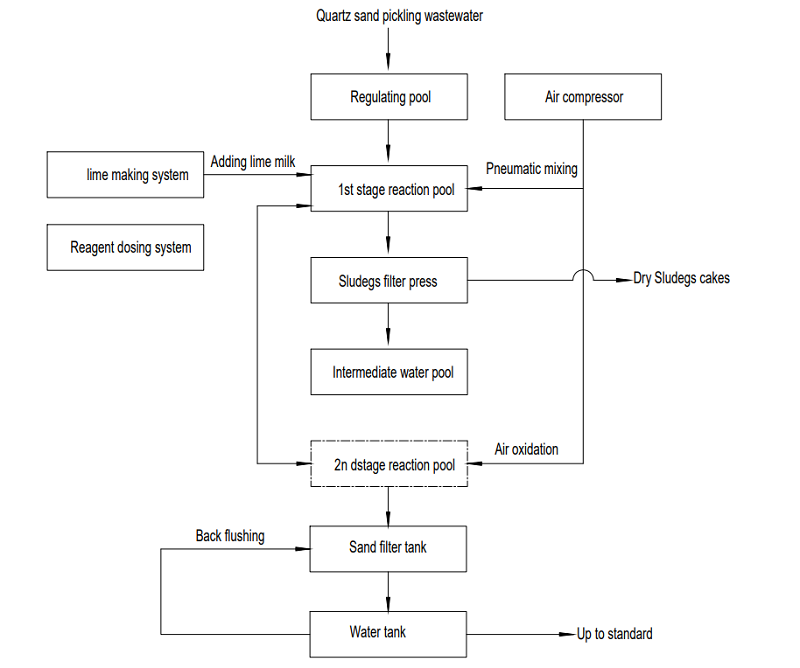

The process flow is as follows

Wastewater regulation

The pickling wastewater is directly discharged into the regulating pool, and the perforated aeration pipe is set in the regulating pool to uniformly mix the wastewater. There is a liquid level meter in the regulating pool to control the start and stop of the sewage lifting pump through the liquid level, and the liquid level meter in the regulating pool plays the role of alarm protection.

First stage neutralization reaction

The wastewater is lifted from the regulating pool to the first stage neutralization reaction pool by the lift pump, and the first stage neutralization reaction mainly removes most of the pollutants in the wastewater.

The neutralization pool is equipped with a liquid level meter. As the wastewater in the lift pump is pumped into the pool, the liquid level of the wastewater in the pool rises. When the set high liquid level is reached, the water in the lift pump stops.

The neutralization pool is equipped with pH meter and pneumatic mixing device. When the lifting pump stops feeding water, the air mixing and lime pump start to work. The dosage of lime milk is controlled by the primary pH control system, and the reaction time is controlled by PLC to keep the wastewater in the reaction pool for a certain time under a certain pH value. When a certain reaction time is reached, the neutralization reaction is finished, and the PLC control is carried out for the next step.

Filtration dewatering

The wastewater sludge after neutralization reaction is settled in batch treatment pool and the settled sludge is dehydrated by plate and frame filter press. This process mainly removes the suspended solids produced by neutralization reaction.

After the first stage neutralization reaction, the fan and the first stage pH control system stop working, and the screw pump starts to pump the settled sludge in the batch treatment pool into the plate and frame filter press for sludge dewatering, and the filtrate flows into the regulating pool by itself. The liquid level meter is set in the pool. As the screw pump continuously outputs the wastewater, the liquid level in the batch treatment pool decreases. When the liquid level drops to the set low level, the screw pump stops working. The dewatered sludge is regularly cleaned and transported for disposal.

Flocculation reaction in second stage batch reactor

The second stage coagulation reaction is continued in the batch treatment pool to completely remove the pollutants in the wastewater and ensure the discharge up to the standard.

When the screw pump stops working, the secondary reaction of the wastewater in the batch treatment tank is continued. The reaction is controlled by PLC and the wastewater is coagulated. The addition of dilute lye, flocculant, coagulant aid and other water treatment agents is completed by the automatic dosing system, and the reaction time is automatically controlled by PLC. The dosing process is automatically controlled by PLC.

Sand filter system

After the coagulation reaction, the soluble pollutants are completely removed, and the suspended solids are intercepted in the process of sand filtration.

The waste water overflow liquid that completes the secondary coagulation reaction is transported from the secondary batch treatment pool to the sand filter tank by the sand filter pump, and the sand filtered water is discharged into the discharge tank.

A liquid level meter is set in the secondary coagulation pool. When the liquid level drops to the set low level, the sand filter pump stops working. After treatment, the waste water is measured and discharged through the discharge pool.

The precipitated sludge in the secondary batch treatment pool is regularly discharged to the wastewater regulating pool by the operators.

The backwashing of sand filter system is carried out by the clean water in the discharge pool delivered by the sand filter water pump, and the backwashing water is connected to the regulating pool.

Main equipment list

|

No |

Name |

Qty |

Remarks |

Working position |

|

1 |

Grille |

1set |

UPVC plate |

|

|

2 |

Oil separation plate |

1set |

UPVC plate |

|

|

3 |

Liquid level meter |

4pcs |

|

|

|

4 |

Sewage lift pump |

2sets |

Operation + standby |

Regulating pool |

|

5 |

Batch processing pool |

1pcs |

Corrosion protection |

|

|

6 |

Screw pump |

2sets |

Operation + standby |

|

|

7 |

Filter press |

1pcs |

|

|

|

8 |

Sand filter water pump |

2sets |

Operation + standby |

|

|

9 |

Sand filter tank |

1pcs |

|

|

|

10 |

Discharge water pool |

1pcs |

Corrosion protection |

|

|

11 |

Air compressor |

2sets |

Operation + standby |

|

|

12 |

Standard Outfall |

1pcs |

|

|

|

13 |

Lime making system |

|

|

|

|

14 |

Reagent dosing system |

|

|

|

|

15 |

Electrical control cabinet |

|

|

|

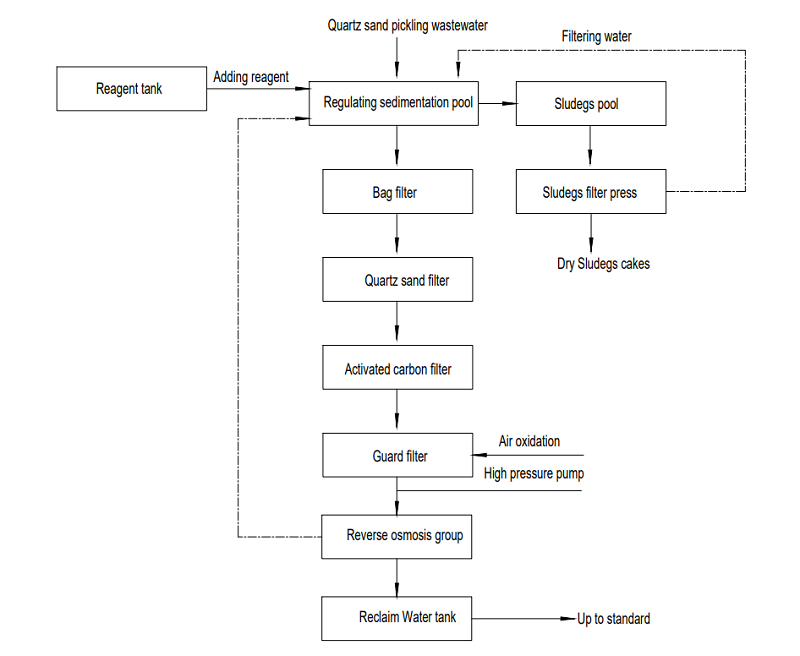

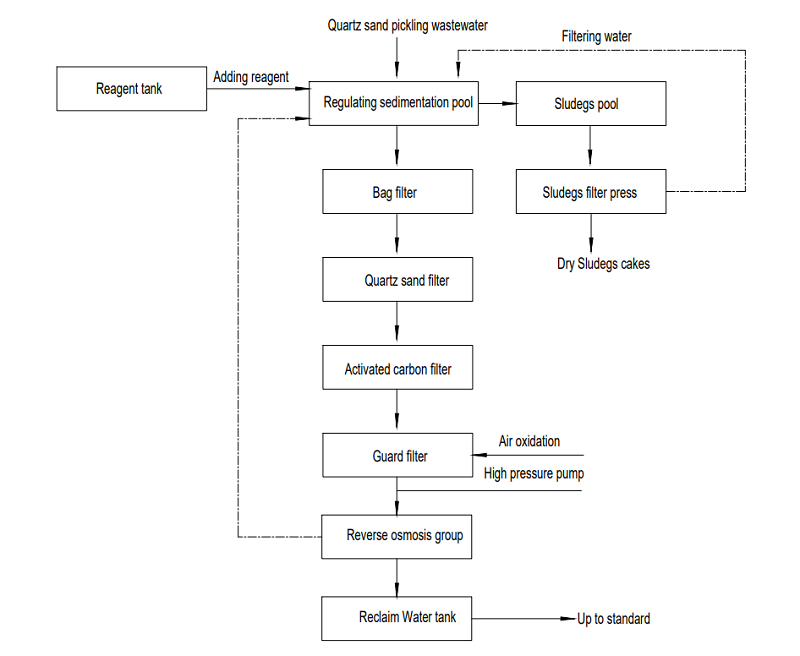

3.Neutralization + pressure filtration dewatering + multistage filtration + reverse osmosis process

Quartz pickling wastewater first enters the regulating sedimentation pool, and then lime water is added to adjust the pH to 8.5 ~ 9.5. After reaction for a period of time, flocculant is added to coagulate the impurities and sludge in water to achieve better solid-liquid separation .The separated sludge enters the sludge pool and is dewatered by the plate and frame filter press before being transported out.

The clear liquid in the upper part of the regulating sedimentation pool is lifted by the raw water pump, filtered by the bag filter, then passed through the quartz sand filter and the activated carbon filter, and then entered the guard filter. After being pressurized by the high-pressure pump, it enters the reverse osmosis group. The produced concentrated water returns to the regulating sedimentation pool and the product water enters the reuse pool for reuse or discharge.

Main equipment list

|

No. |

Name |

Material |

Qty. |

|

1 |

Regulating sedimentation pool |

RCC |

1set |

|

2 |

Sludge pool |

RCC |

1set |

|

3 |

Reclaim water pool |

RCC |

1set |

|

4 |

Water pump |

PP |

1set |

|

5 |

Bag filter |

SUS, PP |

1set |

|

6 |

Sand filter |

FRP |

1set |

|

7 |

Activated carbon filter |

FRP |

1set |

|

8 |

Guard filter |

SUS |

1set |

|

9 |

High pressure pump |

SUS |

1set |

|

10 |

Reverse osmosis machine |

SUS |

1set |

|

11 |

Sludge pump |

|

1set |

|

12 |

Electrical control system |

|

1set |

|

13 |

Pipeline & valves |

|

1each |

For more information about sand washing plant and its waste water treatment,please see www.9silica.com, or contact us directly by +86-18118821087(Whatsapp).