Sinonine

sand washing machine is widely used in sand,gravel, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station and other industries to wash materials. The sand washing machine can remove the impurities covered on the surface of sand and gravel particles, and destroy the water vapor layer of the coated sand particles, so as to facilitate dehydration and play the role of efficient sand washing, so as to obtain high-quality products.

The common sand washing machines of Sinonine are

screw sand washer(spiral sand washing) and

wheel(bucket) sand washer. These two kinds of sand washing machines are very different in structure and application. Sinonine team compares the two kinds of sand washing machines as follows.

Washing principle of screw sand washer and wheel sand washer

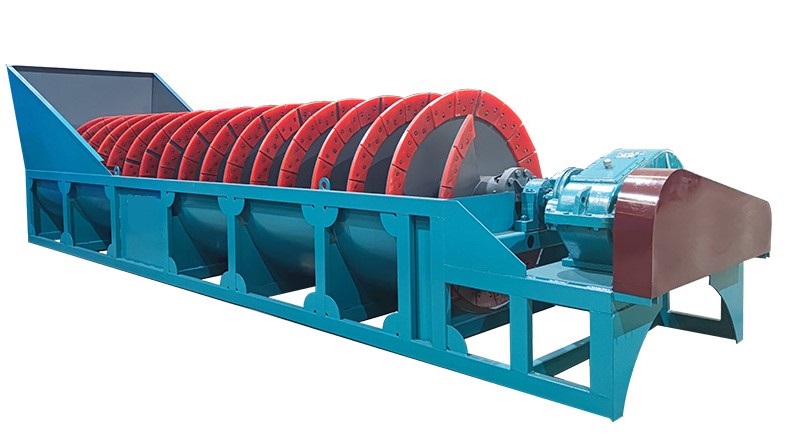

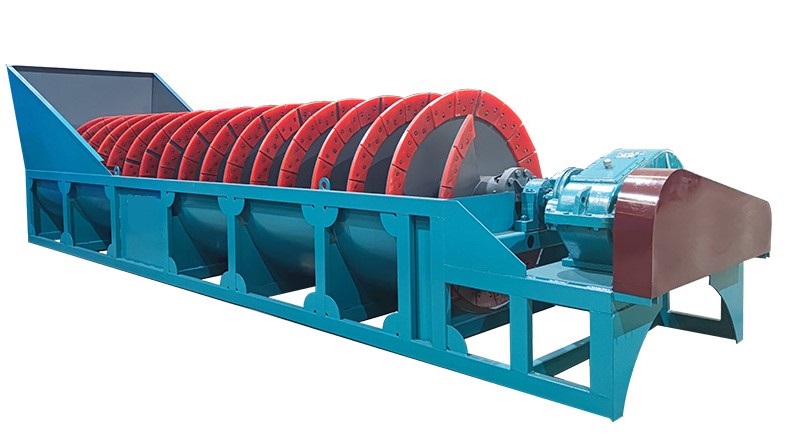

1.Washing principle of screw sand washer

Screw sand washer is divided into single screw and double screw. It is mainly used for washing, grading and impurity removal in highway, hydropower, construction and other industries, as well as washing of fine-grained and coarse-grained materials.

The screw head sinks into the sedimentation tank, the screw is continuously rotated by the motor driven by the reducer, and the clear water is fed by the porous plate at the bottom of the sedimentation tank. The clean water flow carried out by the perforated plate forms an upward flow, and the foreign matters with small specific gravity are brought to the water surface and overflow out of the weir plate to complete the cleaning. The larger particles sink into the tank, and bend the plate in the tank to push the sand upward by the spiral blade. Because the length of the tank is beyond the lower horizontal line, there is a suitable length, in the process of upward pushing, the excess water of the sand is removed, and the separated water flows into the sedimentation tank from the drainage ditch on the other side of the tank bottom.

2.Washing principle of wheel sand washer

2.Washing principle of wheel sand washer

When the wheel (bucket) sand washer is working, the motor drives the bucket wheel to rotate slowly after being decelerated by the triangle belt, reducer and gear. The sand and gravel enter into the washing tank through the feeding tank, roll under the drive of the wheel, and grind each other to remove the impurities covering the surface of the sand and gravel, and destroy the water vapor layer covering the sand particles, so as to facilitate dehydration. At the same time, water is added to form a strong water flow to take away impurities and foreign matters with small specific gravity in time and discharge them from the overflow outlet washing tank to complete the cleaning function. The clean sand and gravel are taken away by the blades, and finally the sand and gravel are poured into the discharge chute from the rotating wheel to get clean particles.

External structure of screw sand washer and wheel sand washer

External structure of screw sand washer and wheel sand washer

The structure of spiral sand washer is narrow and long. It adopts horizontal structure, and the spiral inclination can be adjusted.

The wheel sand washer is of wheel type structure, which is compact and has a certain height.

Cleanliness of screw sand washer and wheel sand washer

The screw sand washer has higher cleanliness for fine size particles, while the wheel sand washer has higher cleanliness for coarse size particles.

Capacity of screw sand washer and wheel sand washer

Both screw sand washer and wheel sand washer can achieve large capacity. Under the same power, spiral sand washer can achieve greater production capacity. This makes spiral sand washer can be configured in large

sand washing plant.

Dewatering function of screw sand washer and wheel sand washer

Dewatering function of screw sand washer and wheel sand washer

The screw sand washer has good dewatering function, and the water content of washed sand can be controlled between 15-20%, which creates better conditions for subsequent dewatering equipment. The wheel sand washer does not have the function of dewatering, and the washed sand needs to be dehydrated by a dewatering screen.

Price of screw sand washer and wheel sand washer

Screw sand washer is relatively high in price, service life and work efficiency. It is a high-end sand washing machine and suitable for high-grade quartz sand washing operation.

The price of wheel sand washer is relatively low. It is an economical and efficient sand washer, and its operating cost is relatively low. It is suitable for ordinary sand washing operation.

Users should fully consider the granularity, composition, output, finished product requirements, economic conditions and production site conditions of raw materials when selecting sand washer, and select the most appropriate sand washer to obtain the best economic benefits.